Part Number: LAUNCHXL-F28377S

Tool/software: Code Composer Studio

Hi,

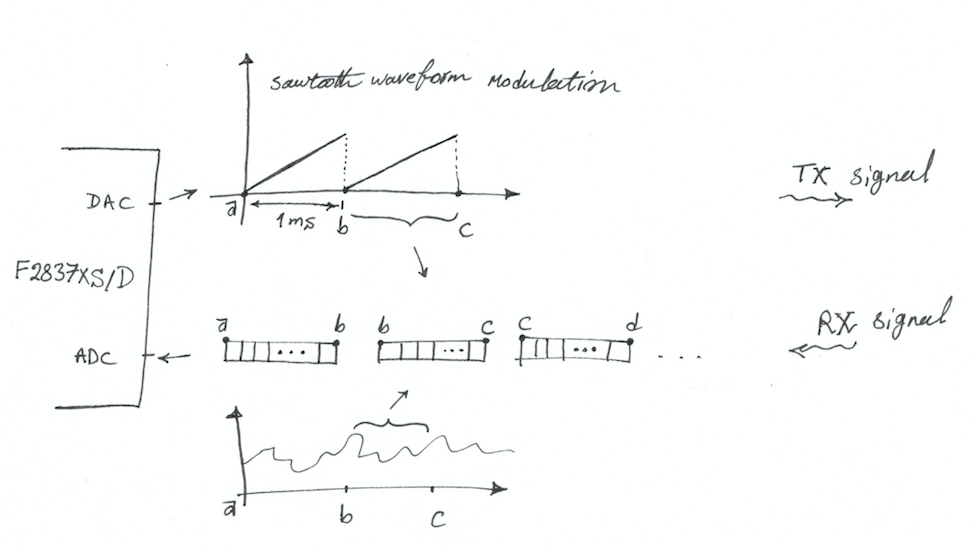

For my application, I need to generate ramp signal waveform with a DAC port and in the other hand, sampling the received signal at the same time with ADC port.

Please tell me your ideas and if any sample code is available for that?

Thanks for your help.

Best regards,

Amin