Other Parts Discussed in Thread: DRV8301

Hi Champs,

I get my customer motor and motor SPEC is 6000rpm @ 48V. I used DRV8301+69M controlCARD. DC input is 48v. I ran Lab02a/Lab02c and get different current waveform. I found out that RS value is very small value after RS state. However, I check the Rhf/Lhf which are not small as RS.

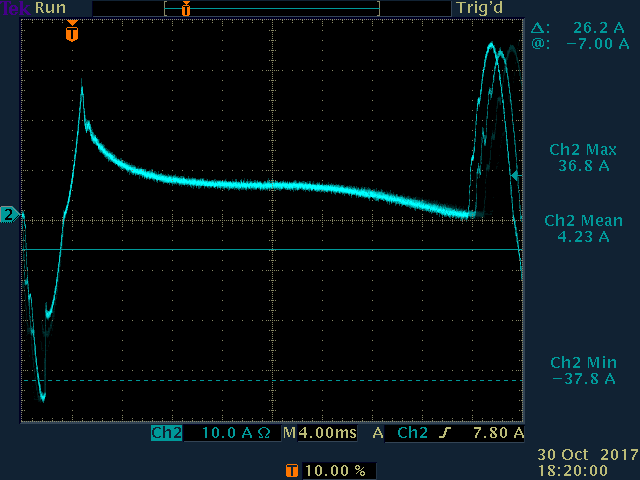

I found out when I used default PWM freq=45khz, RoverL current waveform looks like weird. I change the PWM freq = 40Khz which RoverL waveform looks like more sinusoidal. However, when controller enter Ramp up state which generated a peak current at first then sinusoidal. Please see current waveform below. After ramp up state, motor stop in RatedFlux state. I change USER_MOTOR_FLUX_EST_FREQ_Hz up to 100 but still failed at RatedFlux state.

I also change USER_R_OVER_L_EST_FREQ_Hz freq to 100. In DRV8301 project, USER_R_OVER_L_EST_FREQ_Hz default value is 300hz.

I also use Lab02c to did motor ID but also failed at RatedFlux state.

I attached my user.h in post. Could you please tell me which variable should I change to pass motor ID ? thanks !

There is one more thing I would like to know. When I used Lab02c and PWM freq = 45Khz. RS state current isn't DC and it is Sawtooth wave. Could you please tell me why ?

PWM=45Khz, RoverL current waveform

PWM freq = 40Khz, RoverL waveform

Ramp up peak current at PWM=40khz

EST_State_Rs current @ PWM=45Khz