Other Parts Discussed in Thread: BOOSTXL-DRV8301, MOTORWARE

Hi Everyone,

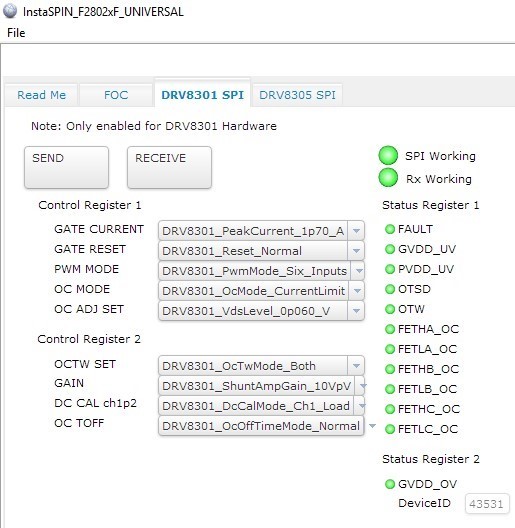

I am trying to control the speed of a small Hobbyking BL1230 5300kv Brushless Inrunner Motor using an F28027F launchpad and a BOOSTXL-DRV8301. I am using the example Simulink model (45124) where a BLY172S-24V-4000 motor is used.

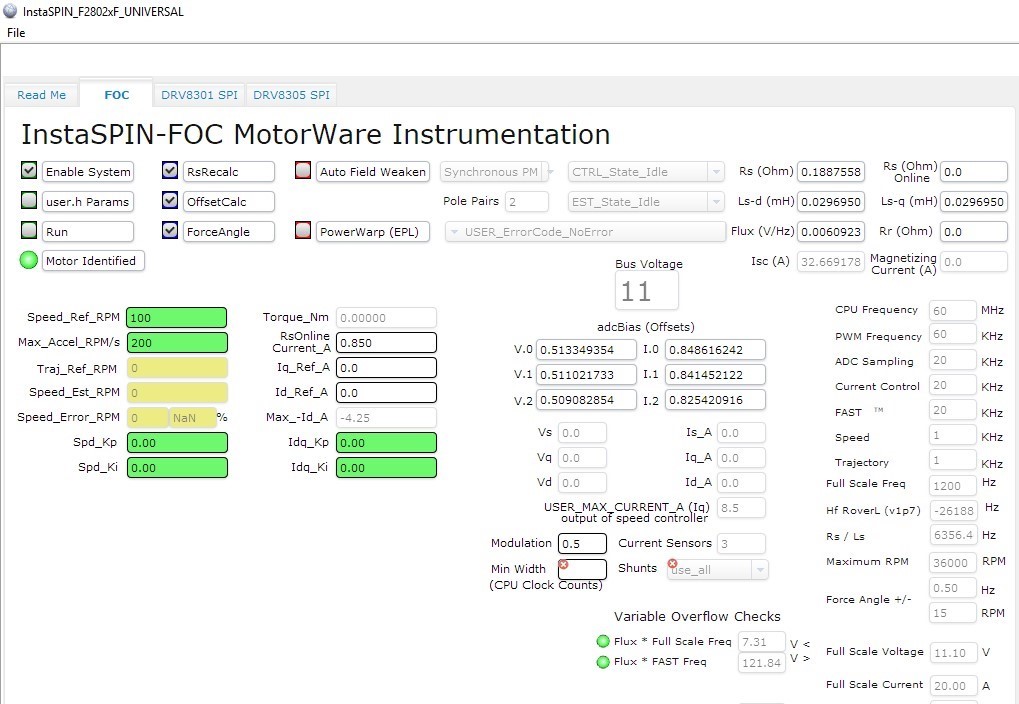

I was able to successfully run Lab2b through Motorware using the Universal GUI method and have obtained the motor identification parameters. I have also included these parameters in my Matlab setup file (c28027pmsmfoc_data) and I am able to successfully compile the code. However, the problem I am facing is that my motor shaft seems to be oscillating between two poles.

So far, I have reduced and eliminated the Kp & Ki gains in the Simulink Speed Controller Block and also the Sliding Mode Observer Gains (SMO) in the Matlab setup file. I am currently under the impression that the source of this problem is a setup/initialisation process that is unable to be completed? (Please correct me if I am wrong).

Has anyone experienced a similar problem with their motor before where the shaft continues to oscillate between two poles? Any help will be greatly appreciated.

Best Regards,

Riley