Other Parts Discussed in Thread: MOTORWARE, , TMDSHVMTRINSPIN

Hi all,

I need your help with a motor controller using the TMS320F28069F processor (3 year old design). With a simple engine test bench (ACIM engine, 2-pole, 0.55W) with the HVKit (TMDSHVMTRINSPIN & TMDSCNCD28069MISO) experiments have been performed with the InstaSPIN_UNIVERSAL tool (Lab02b-MotorID & Lab11a project). The latest MotorWare version 1.01.00.18 is used.

There are the following problems (detailed documents are also available):

- The determined motor parameters (Lab02b) differ depending on the set PWM frequency.

|

|

TI-High-Voltage-Motor-Control-Kit mit mit ACIM-Motor (2pin, 0.55W) InstaSPIN_F2806xM_UNIVERSAL (proj_lab02b) |

|||

|

PWM-Frequency |

USER_MOTOR_ Rr (Ω) |

USER_MOTOR_ Rs (Ω) |

USER_MOTOR_ Ls_d (H) |

USER_MOTOR_ MAGNETIZING_CURRENT (A) |

|

12kHz |

3.8303122 |

4.0975060 |

0.0068570803 |

2.1514337 |

|

16kHz |

3.7165627 |

4.4100050 |

0.014940408 |

2.0349829 |

|

18kHz |

2.4062523 |

4.4462552 |

0.055235102 |

2.1070599 |

|

20kHz |

1.9003125 |

4.0425057 |

0.065108276 |

2.1640532 |

|

24kHz |

1.3662508 |

3.6949999 |

0.068892903 |

2.5442357 |

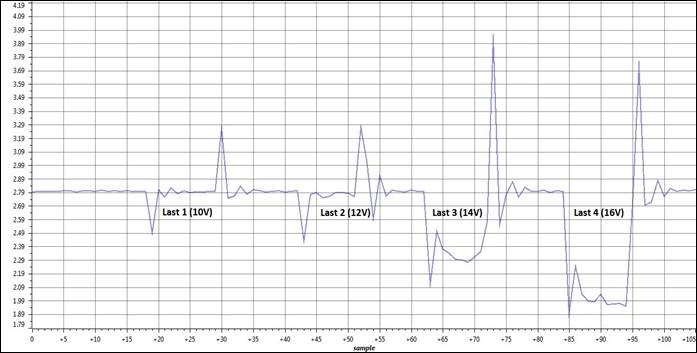

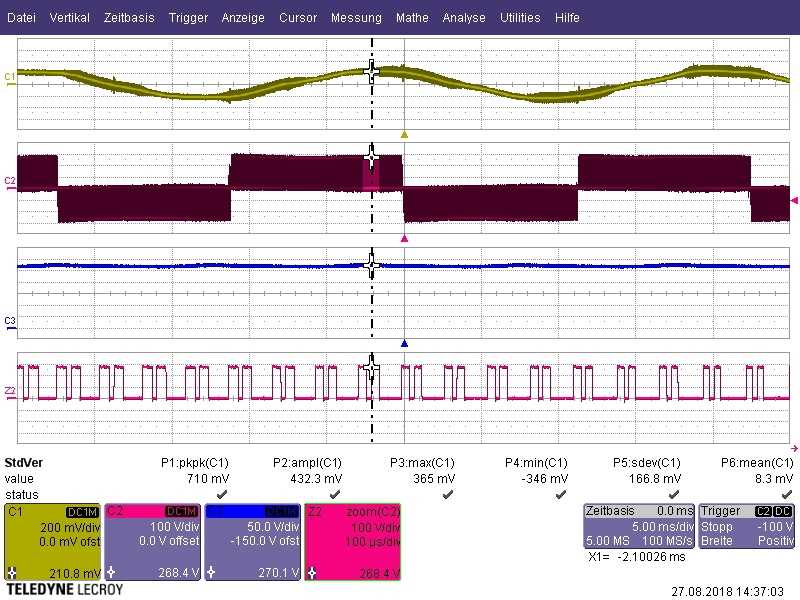

- When the PowerWarp (EPL) is deactivated, the speed is not reached and the motor stops. The application (Lab11a / 18kHz) has to be reloaded.

-

With the example project (Lab11a / 18kHz), the speed drops at a load of more than 0.3kW.

Invertek-P2-Frequency converter

Optidrive P2 ODP-2-22220-1KF42-SN (Vectorcontrol/16kHz)

TI-High-Voltage-Motor-Control-Kit

InstaSPIN_F2806xM_UNIVERSAL (proj_lab11a/18kHz)

Braking load

Engine power

Engine current

Intermediate circuit voltage

Rotor speed

Torque

Engine current

Intermediate circuit voltage

Rotor speed

0 (0V)

0.04W

1.4A

310V

2797rpm

0.08Nm

0.44A

306V

2803rpm

1 (10V)

0.16W

1.4A

298V

2787rpm

0.52Nm

0.85A

291V

2800rpm

2 (12V)

0.24W

1.4A

292V

2778rpm

0.76Nm

0.90A

287V

2790rpm

3 (14V)

0.33W

1.5A

285V

2761rpm

1.17Nm

1.35A

278V

2403rpm

4 (16V)

0.45W

1.7A

276V

2738rpm

1.52Nm

1.70A

270V

1903rpm

5 (18V)

0.58W

2.1A

267V

2705rpm

6 (20V)

0.72W

2.5A

258V

2650rpm

Thanks for your help and kind regards,

Miriam