Hello,

My customer want to generate 8 paired PWM output like below picture to drive full bridge.

Black: 1A, Red: 2A, Blue:3A, Green: 4A, Orange 1B, Grey: 2B, Purple:3B, Light green: 4B

The requirement is :

1. 50% duty cycle square wave, frequency is adjustable

2. It always has 90° phase shift between 1A and 1B. 2, 3, 4 waveform follow up 1A and 1B after a phase shift.

3. Adjustable phase difference between 2A and 1A, 3A and 2A, 4A and 3A.

4. Adjustable phase difference between 2B and 1B, 3B and 2B, 4B and 3B.

5. 5A, 6A, 7A, 8A is same with 1A, 2A, 3A, 4A.

6. 5B, 6B, 7B, 8B is same with 1B, 2B, 3B, 4B.

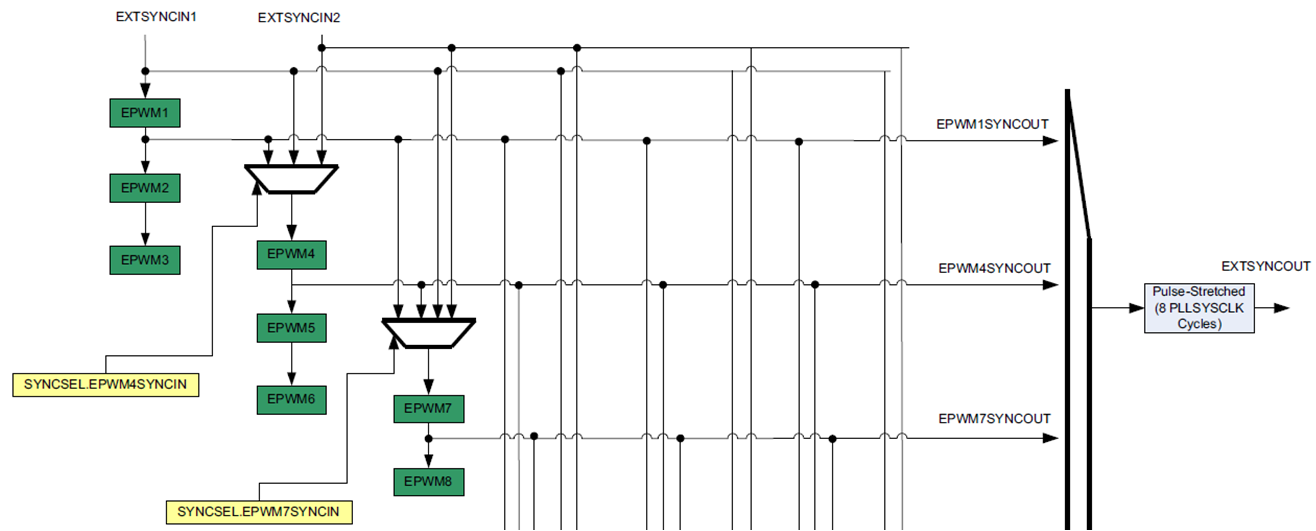

Could you let me know how to configure EPWM1 to EPWM8 while they are working on below 3 parallel mode?