Part Number: TMS320F280049

Other Parts Discussed in Thread: C2000WARE

Hello,

My customer needs to generate a signal in the order of 100 kHz using ePWM or HRPWM. The choice between both is pending the THD assessment, but likely it will be the HRPWM since (after the table 19-1 in the TRM) the ePWM would give a 10-bit resolution at this frequency which is a bit low. The signal period is a multiple of the CPU core frequency. He pre-computes a table of values that will be transferred by DMA to the ePWM/HRPWM.

Questions:

- Assuming he uses the ePWM, is "C2000Ware_1_00_06_00\device_support\f2833x\examples\epwm_dma" the closest example to the above?

- Do we have any HRPWM example he could leverage?

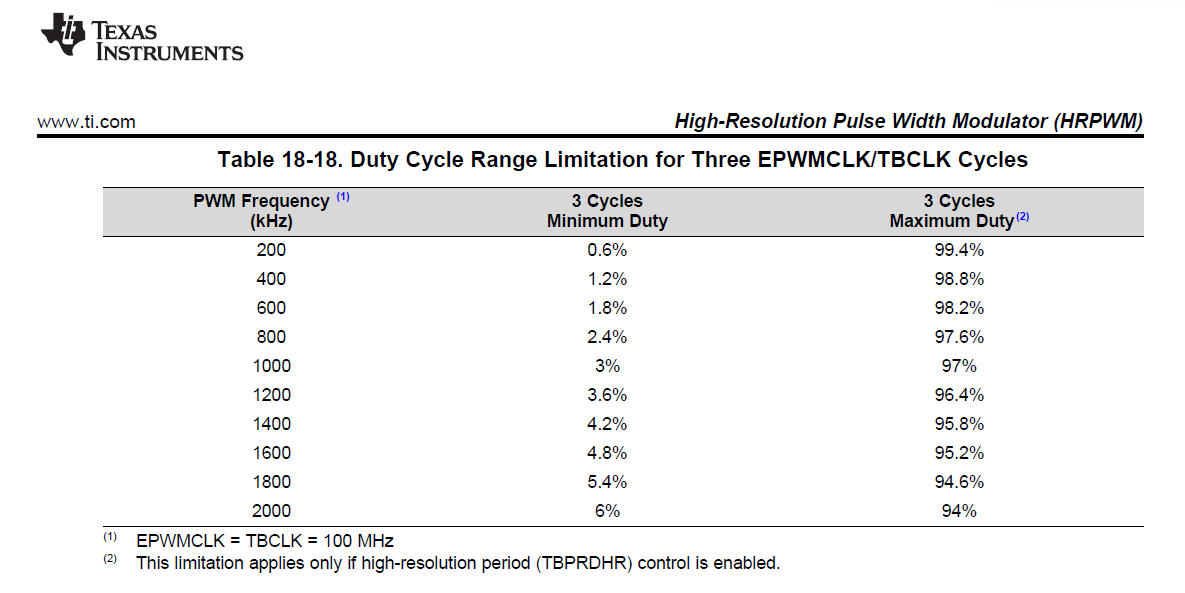

- The ePWM and HRPWM duty cycle will be changed for each PWM period. What is the highest update rate at which the duty cycle register may be updated? The current thought is to have a 4 MHz PWM period, but would 8 or 16 work as well?

Thank you.

Best regards,

François.