Other Parts Discussed in Thread: C2000WARE

Tool/software: Code Composer Studio

Hi,

I have a problem that is related to EPWM output from DSP TMS320F28377S.

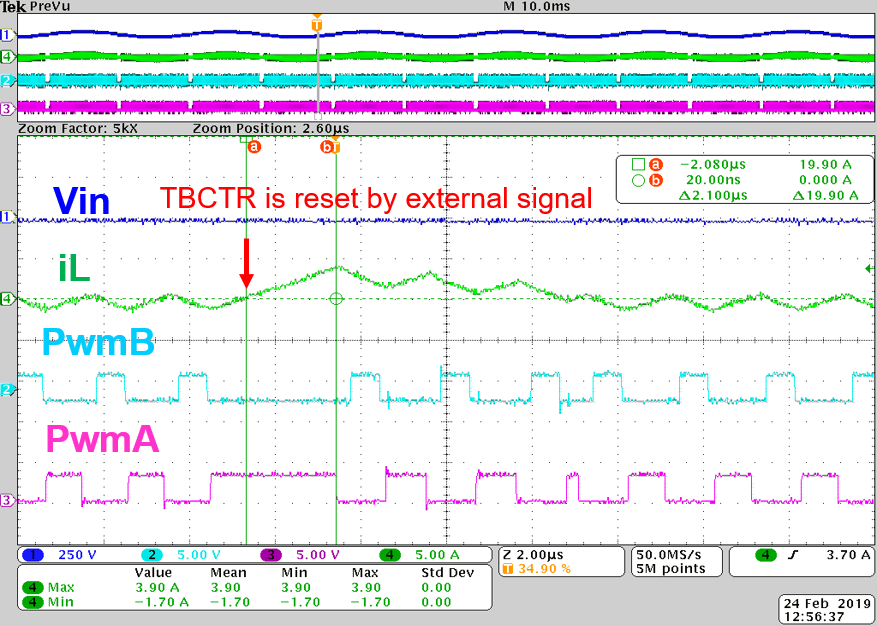

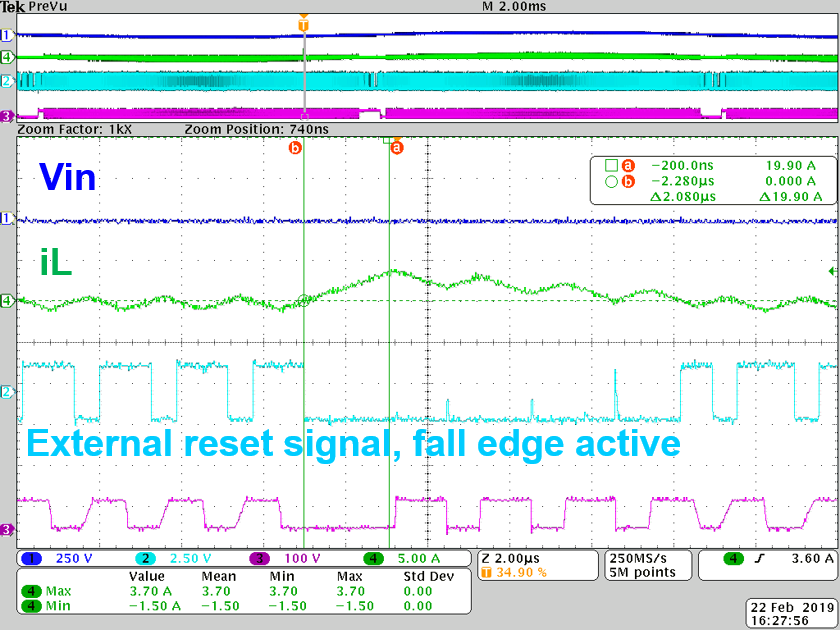

In my code, the EPWM7 output is updated based on the sensing signal and real-time calculation of the duty cycle in one interrupt. As shown in the following picture, the PWM output is occasionally all high in A and all low in B in one switching cycle, looking like a glitch or bug. i used complementary mode in PWM generation. And such glitch occurs in very low frequency (sometimes it takes ten seconds to capture one glitch). The sensed external signal and real-time calculation should be all right. Since my sampling frequency is 50kHz, and switching frequency is averagely 300kHz, if something wrong with the calculation and sensing signal, the PWM glitch will last for several switching cycles instead of only one cycle and occurs in so low frequency. so it looks more like a PWM glitch when updating the duty cycle.

I wonder, what will cause the EPWM module glitch or bug like this? How can i avoid such phenomenon?

By the way, the initialization function of the PWM is shown below. Values for EPWM_TIMER_TBPRD, EPWM_CMPA, EPWM_CMPB, EPWM_TIMER_PHASE, RED and FED are updated based on the calculation in one ADC interrupt.

// code/////////////

void InitEPwm7()

{

// Setup TBCLK

EPwm7Regs.TBCTL.bit.CTRMODE = TB_COUNT_UP; // Count up

EPwm7Regs.TBPRD = EPWM_TIMER_TBPRD; // Set timer period

EPwm7Regs.TBCTL.bit.PHSEN = TB_ENABLE; // Enable phase loading

EPwm7Regs.TBPHS.bit.TBPHS =0x0000; // Phase is 0

EPwm7Regs.TBCTL.bit.PRDLD = TB_SHADOW; //

EPwm7Regs.TBCTL2.bit.SYNCOSELX=1; //extended selection for sync out, EPWMxSYNCO = CMPC

EPwm7Regs.TBCTL.bit.SYNCOSEL = 3; //0:Sync Output Select is sync signal;1: when TB counter = zero; 3: extended,

EPwm7Regs.TBCTL.bit.HSPCLKDIV = TB_DIV1; // Clock ratio to SYSCLKOUT

EPwm7Regs.TBCTL.bit.CLKDIV = TB_DIV1;

//

// Setup shadow register load on ZERO

EPwm7Regs.CMPCTL.bit.SHDWAMODE = CC_SHADOW;

EPwm7Regs.CMPCTL.bit.SHDWBMODE = CC_SHADOW;

EPwm7Regs.CMPCTL.bit.LOADAMODE = CC_CTR_ZERO;

EPwm7Regs.CMPCTL.bit.LOADBMODE = CC_CTR_ZERO;

EPwm7Regs.CMPCTL2.bit.SHDWCMODE = CC_SHADOW;

EPwm7Regs.CMPCTL2.bit.LOADCMODE = CC_CTR_ZERO;

//

// Set Compare values

EPwm7Regs.CMPA.bit.CMPA = EPWM_CMPA; // Set compare A value

EPwm7Regs.CMPB.bit.CMPB = EPWM_CMPB; // Set Compare B value

EPwm7Regs.CMPC = EPWM_TIMER_PHASE; // 0.5 Ts

//

// Set actions on outputA, EPWM7A is the original PWM for SR switch

EPwm7Regs.AQCTLA.bit.CAU = AQ_SET; // Set PWM1A on event A, up count

EPwm7Regs.AQCTLA.bit.CBU = AQ_CLEAR; // Clear PWM1A on event B, up count

//

// Set Dead-Band Generator

EPwm7Regs.DBCTL.bit.IN_MODE = DBA_ALL; //EPWMA is the source for both falling edge and rising edge

EPwm7Regs.DBCTL.bit.OUT_MODE = DB_FULL_ENABLE; // enable dead-band module, bothFED and RED are active

EPwm7Regs.DBCTL.bit.POLSEL = DB_ACTV_HIC; // Active high complementary

EPwm7Regs.DBRED.bit.DBRED = RED; // set dead time before turning on SR switch

EPwm7Regs.DBFED.bit.DBFED= FED; // set dead time before turning on AC switch, Tr

// turn off gate signals when Vo over voltage through trip 1

EALLOW;

EPwm7Regs.TZSEL.bit.OSHT1 = 1; // enable T1 as the trigger signal

EPwm7Regs.TZCTL.bit.TZA = 2; // force EPWM7A to be LOW

EPwm7Regs.TZCTL.bit.TZB = 2; // force EPWM7B to be LOW

EDIS;

// turn off gate signals when over current through trip 2

EALLOW;

EPwm7Regs.TZSEL.bit.OSHT2 = 1; // enable T2 as the trigger signal

EPwm7Regs.TZCTL.bit.TZA = 2; // force EPWM7A to be LOW

EPwm7Regs.TZCTL.bit.TZB = 2; // force EPWM7B to be LOW

EDIS;

// turn off gate signals when over current through trip 3

EALLOW;

EPwm7Regs.TZSEL.bit.OSHT3 = 1; // enable T3 as the trigger signal

EPwm7Regs.TZCTL.bit.TZA = 2; // force EPWM7A to be LOW

EPwm7Regs.TZCTL.bit.TZB = 2; // force EPWM7B to be LOW

EDIS;

}

I really appreciate it if you could give me any hint or suggestions. This problem is really critical for my whole experiment.

Looking forward to your reply.