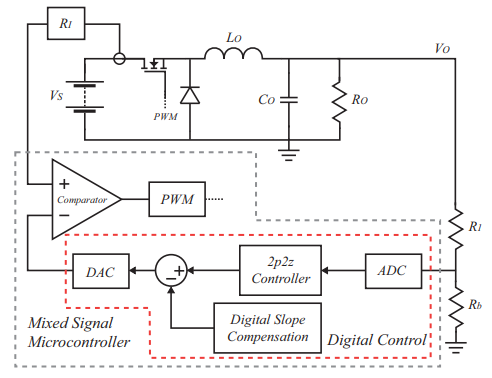

I'm using the TMS320F280049 for a 4 switch 3-phase interleaved bi-directional converter as shown in the diagram. I have questions regarding the CMPSS module to implement peak current mode control by using the inductor currents. The inductor currents range from 0V to 3.3V where 0V = -110A, 3.3V = +110A and 1.65V = 0A. The input to the positive terminal of the comparator are each inductor phase currents.

(1) There is a point during operation when Buck and Boost are required, i.e. all MOSFET's are switching. I need to connect 2 comparators in parallel to facilitate the Buck and Boost sections of the converter as the reference to the comparator is the sum of the ramp signal plus the output of a digital compensator. Each compensator of the Buck and Boost will have different coefficients and hence require two comparators. Can you confirm that it's not possible to implement Buck and Boost with one comparator module?

(2) How can I facilitate (1) in the reverse direction given the inductor current is negative with respect to the 0A (1.65V) reference point? Would I need to invert the output of the digital compensator for either the Buck or Boost and then sum this with the rising ramp signal?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.