Part Number: TMDSCNCD28388D

Other Parts Discussed in Thread: DP83822IF, DP83822I, DP83822HF, DP83822H

Hi, Ive a doubt regarding clk distribution in controlBoard.

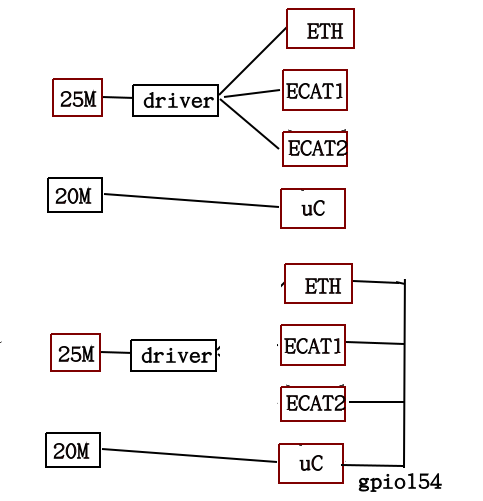

Control board uses an external clk and a clk driver to distribute clk to ethercat/ethernet PHY and uC.

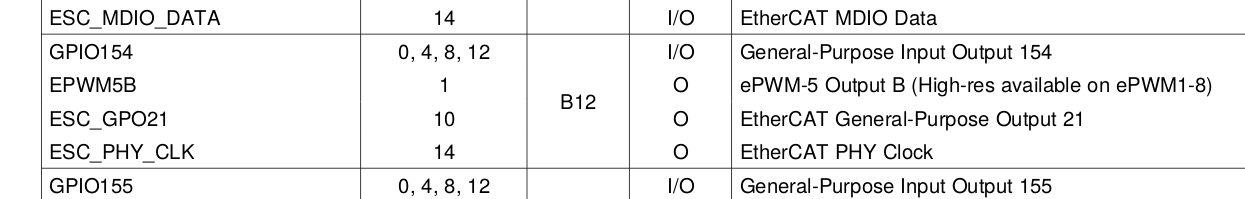

The question is why to do these if the uC has the multiplexing capability to use crystal/external clk and output from gpio154

I've paste here the controlBoard implementation detail where it use a external clk and a driver with selection capabilities using jumpers and after that mine implementation with only one external clk directly coupled to uC and then PHY use pin gpio154.

Is mine approach correct? Should it be work ok? which is the criteria to choose one or the other?

thanks in advance and best regards.

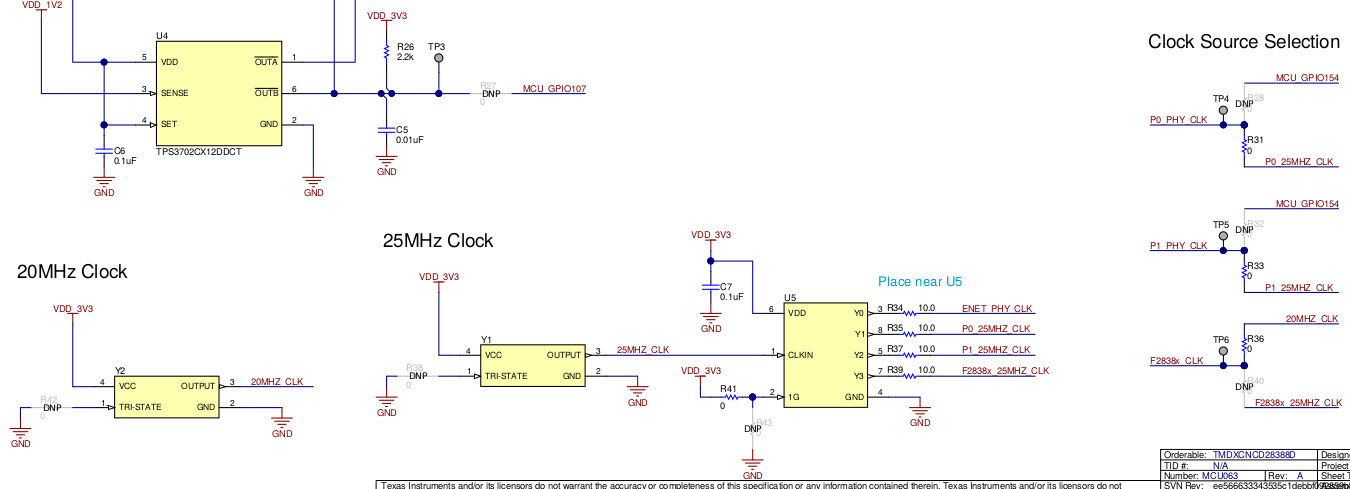

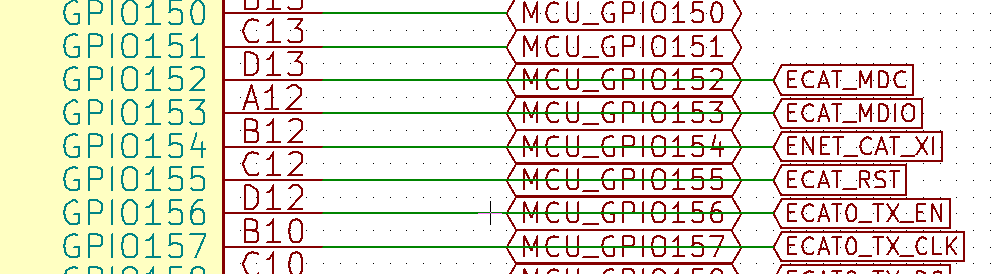

Control Board CLK page

clk distribution on control board. one external clk plus clk driver

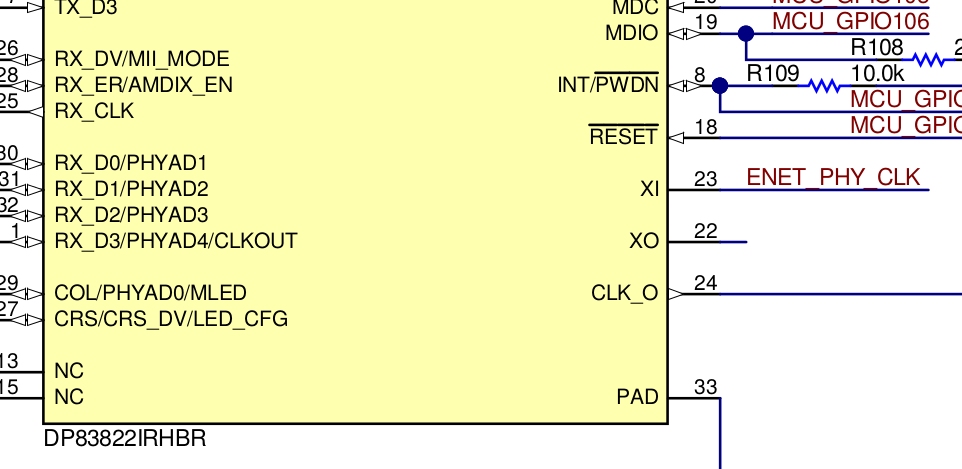

clk driver -> ethernet

the clk comes directly from driver and not from uC pin.

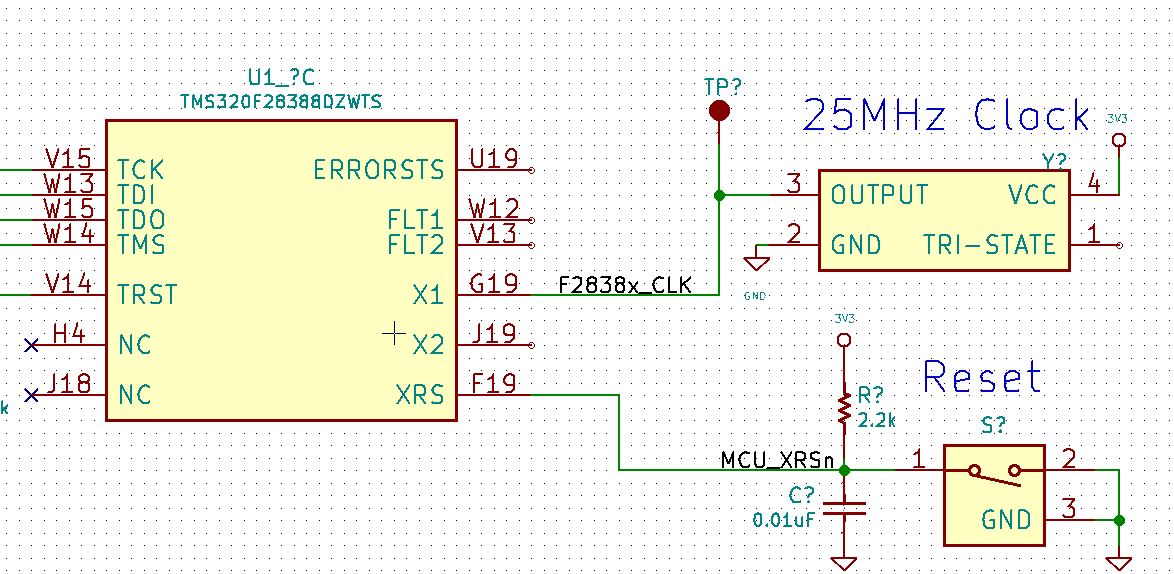

Mine approach, external clk IC to uC as the only main system CLK

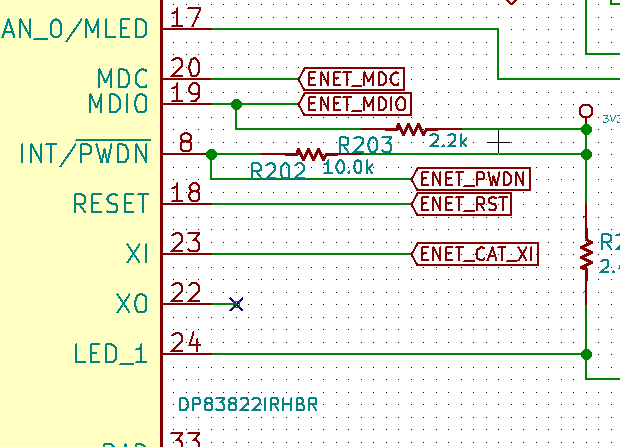

gpio156 multiplexed as ethercat/ethernet clk -> ethernet PHY pin XI

gpio154 uC multiplexed as ethercat/ethernet clk (by firnware)