Other Parts Discussed in Thread: C2000WARE

Hi Team,

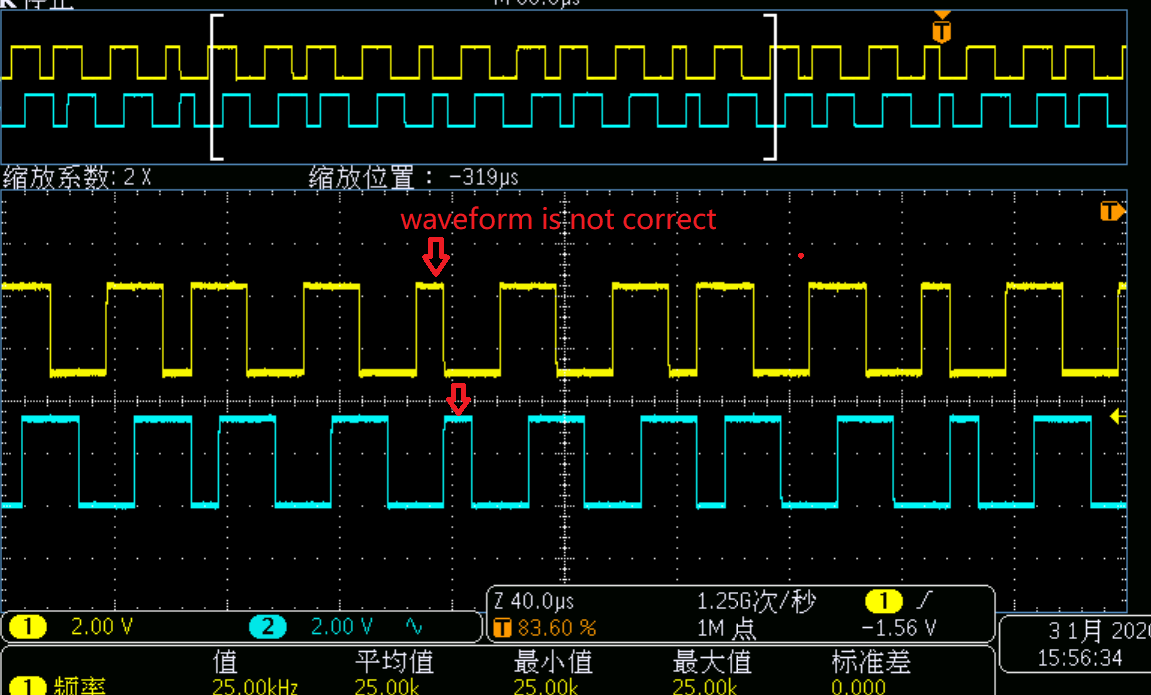

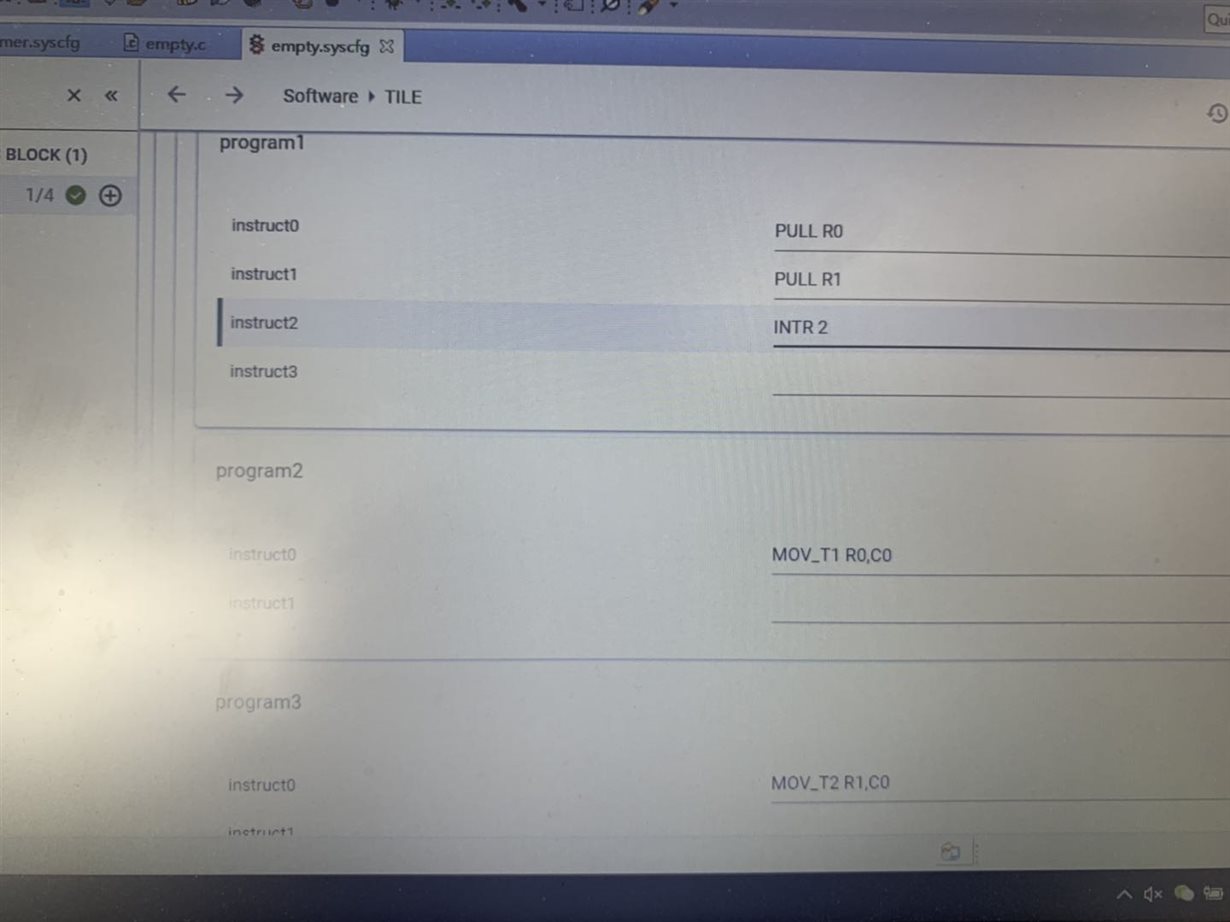

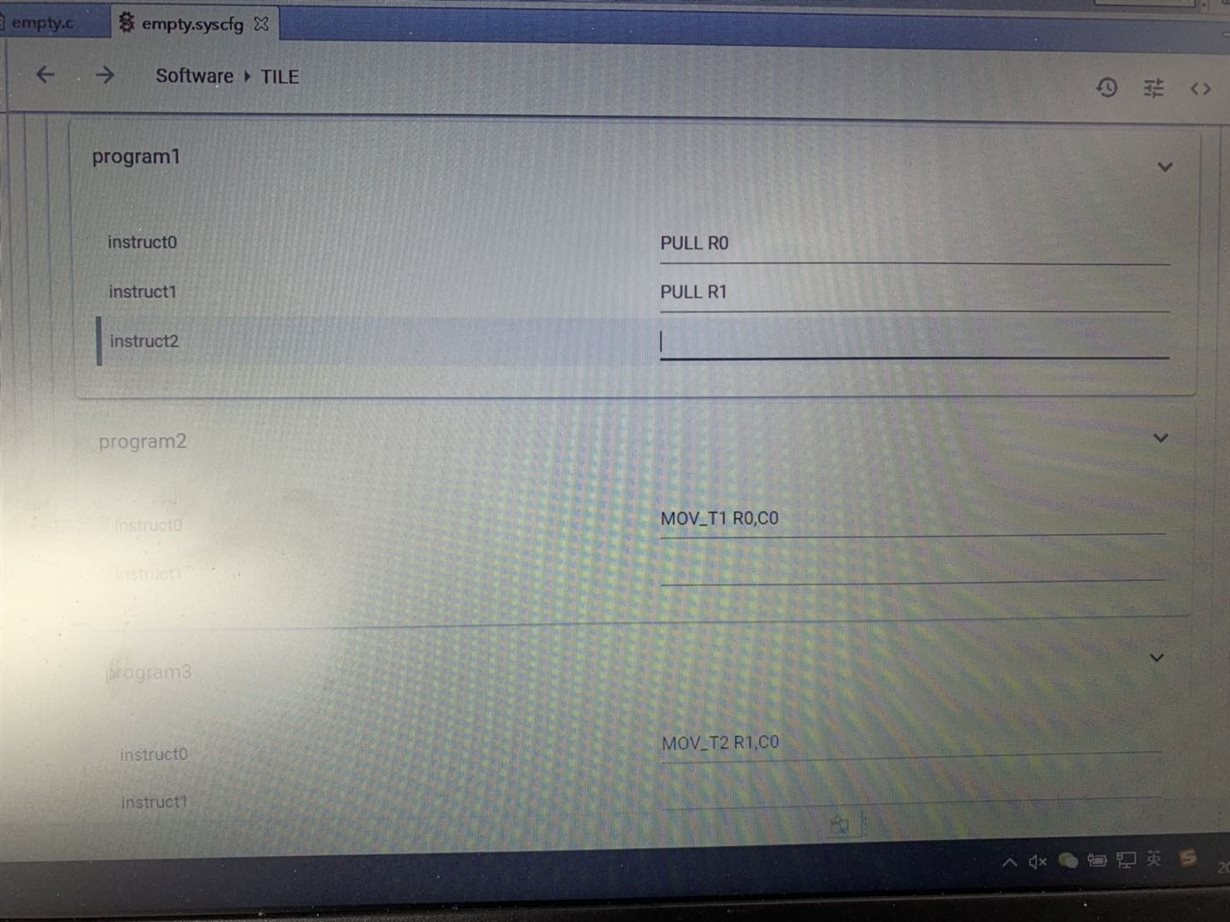

My customer are working on PTO function with CLB tool, now face a strange issue, the CLB configuration is only for PWM waveform generation which duty cycle is fixed at 50%, the simulation waveform is correct, but sometimes the real output waveform is not correct as the below showed.

the code is modified from the example “clb_ex3_auxiliary_pwm”, the hardware is using F280049C Launchpad.

C:\ti\c2000\C2000Ware_2_00_00_03\driverlib\f28004x\examples\clb

Could you help reproduce this issue and find if anything wrong? Why the real output waveform is not the same as the simulation waveform? Thanks a lot.