Other Parts Discussed in Thread: BOOSTXL-DRV8320RS

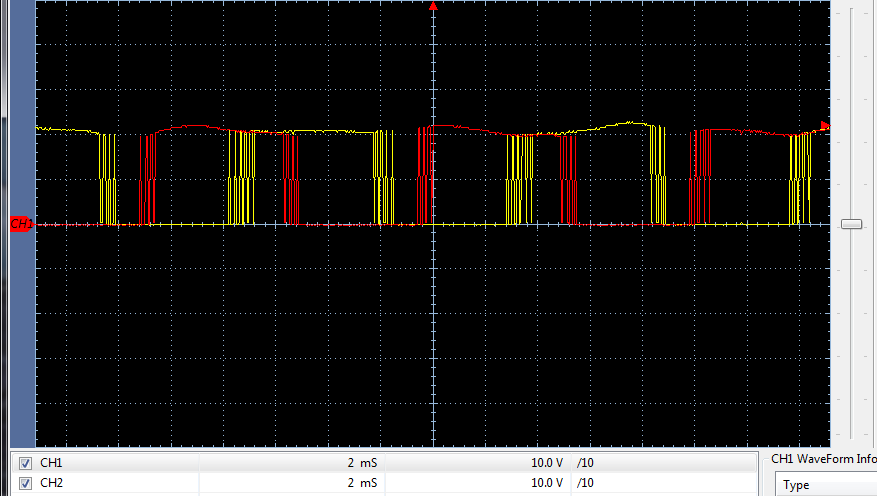

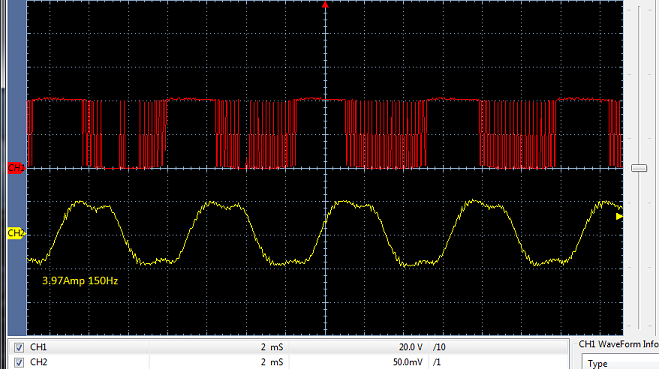

Why motor to vibrate near end of LC test and still be Identified=1 (is05_motor_id.c)? No matter what value USER_MOTOR_FLUX_EXC_FREQ_Hz, motor vibrates <550Hz at any RES/IND current setting (user.h). Yet RS, CL1, CL2, first part LC very stable rotor, identified seems to write bad data for last part of course LC and later Est_State_Online vibrates. Oddly inverter PWM has very little if any sine wave artifact but seems ok accept for the random out of phase pulses randomly bucking the rotor field on all 3 phases.

Inverter PWM has odd glitching, vibration smooths out >510Hz (5.1Krps), still random rotor field bucking occurs. This 12 pole PM motor runs flawless from 6 step commutation (6.2Krpm) via another MCU. This brand new x49c launch pad with BoostXL-DRV8320RS and motor SDK should seemingly not have PWM glitching issues. It would not be logical to test this HW on much larger PM motor under hard commutation as PWM glitching occurs on test bench expendable motor.

The BoostXL-DRV8320RS installed Site 2 and wonder if ePWM or PGA path errata, some how causing motor vibration? TI engineers please to confirm even remedy glitching PWM issue Site 2, MCU B silicon. No PGA 4, 6, 2 filters enabled Site 2. No blanking window codes (is05_motor_id.c). Site 2 ePWM generators GPIO order (A0,1 - B6,7 - C2,3) jumps over B generator ePWM module for D middle phase. It seems PinMux B6,7 is generator D so order seems odd. Rom calls to Park/Clarke expect out of phase signals? I see code (hal.h) ADC samples (Id/Vd) array[n] order compensates but is that actually working? Why is motor vibrate when it was extremely smooth OL, CL1,CL2 is 20Hz but last part LC has vibrates rotor? How can LC vibration be remotely correct SW behavior with intended purpose? Has TI confirmed both Site1 & Site2 produce the exact same motor ID conditions? Why would Site1 be consider placement drv8320rs by engineer to cover up launch pad LED's and only 1 booster pack? That would simply be clumsy investigation at best.

1. ePWM: An ePWM Glitch can Occur if a Trip Remains Active at the End of the Blanking Window?

2. PGA: Output Filter Path is Not Supported?