Hi,

1. We are trying to implement PID controller

2. We need to maintain temperature of a Oven & we are trying to write C code for that, which can control pulse of 2.5 seconds to SSR which in turn control Oven On/off

3. We studied many PID controllers available in market like Delta Electonics, UTAdvanced, Cautoni-Swastik and some other also.

They all use Proportional band(Pb), Ti & Td instead of Kp,Ki & Kd .

Ultimately we finalized on Delta Electronics PID and saw how it works. It uses Pb, Ti & Td

4. We had a word with Delta Electonics In Taiwan, they said they are using this formula in PI Controllers. Reply from Delta Electronics:

They apply integral once PV start falling : drive.google.com/.../view

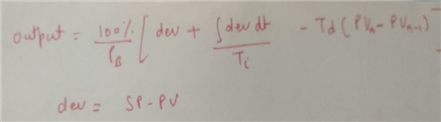

5. Since we are doing PID control so we are using this formula:

Output :

drive.google.com/.../view

Output Range: 0 to 100%

Pb is in degree C (Not sure it should be in Celsius or percentage, but with celsius we are getting nearby results.)

Ti is in seconds

Td is in seconds

Ioffset we are not using at the moment, since we don't know how to calculate it.

6. Derivative term is subtracted to avoid derivative kick. So derivative term is subtracted. No filter here is applied yet though. many papers I found apply derivative filter also.

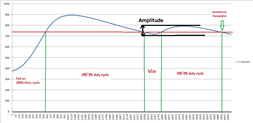

7. We had done autotuning by Astrom-Hagglund(Relay) method, same is done in Delta Electronics PID controller DTC1000, whose manual is attached.

a) Ti, Td calculated by us is same as values calculated by Delta PID

b) Pb we have just copied from what Delta Electronics PID gives, we noticed from multiple test on Delta Autotune PID, that Pb=3.69*(Amplitude)

where Amplitude is difference between max and min temperature goes during Autotune cycle as in image

8. Now we put the formula, as in code attached. Issue is first peak during maintain temperature goes very high upto 10C it goes, and we still tried only setpoints upto 100C only.

9. One issue is Integral WIndup just keeps on growing. SO we implemented this:

e2e.ti.com/.../teaching-your-pi-controller-to-behave-part-vii

10. issue with this also, that integral windup keeps on growing and dont get clamped at some point.

As proportional term falls with decrease in temp, Max_limit_integral also keeps on growing

11. Can you please help in this. Our basic c code is attached. Our observation is once setpoint is crossed, the integral don't fall immediately (fast enough) or it gets accumulated so much that it takes time to fall off, which leads to spike in PV(process variable)

12. Here is code, what could be we are doing wrong?

void compute_pid_duty_cycle(void)

{

/* get error */

error = setpoint_temperature - input_temperature;

if(first_time)

{

first_time = 0U;

previous_temperature = input_temperature;

}

/* calculate duty cycle */

if(error > pb)

{

output_duty_cycle = 100.0f;

}

else if(error < -pb)

{

output_duty_cycle = 0.0f;

}

else

{

/* calcukate p term */

p_term = (100.0f * error) / pb;

/* differential error */

d_term = (input_temperature - previous_temperature)/dt; //dt = 1seconds

d_term = d_term * td * 100.0f / pb;

/* calculate i term */

if((p_term + i_term - d_term) < 80.0f)

{

i_term = i_term + (100.0f / (pb * ti))*error*dt;

}

/* Compute PID Output */

output_duty_cycle = p_term + i_term - d_term;

unclamped_output = output_duty_cycle;

if(output_duty_cycle > c_output_max)

{

output_duty_cycle = c_output_max;

}

else if(output_duty_cycle < c_output_min)

{

output_duty_cycle = c_output_min;

}

else

{

}

}

/* Remember some variables for next time */

previous_temperature = input_temperature;

}