Other Parts Discussed in Thread: TMDSADAP180TO100, TMS320F280049C, , C2000WARE, AMC1300

Tool/software: Code Composer Studio

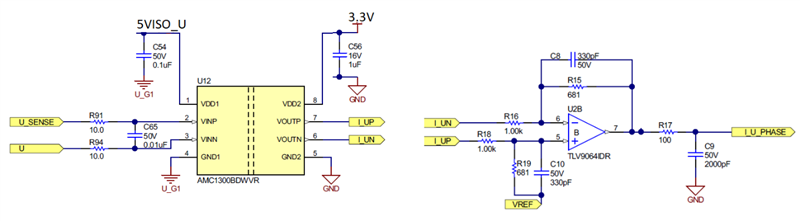

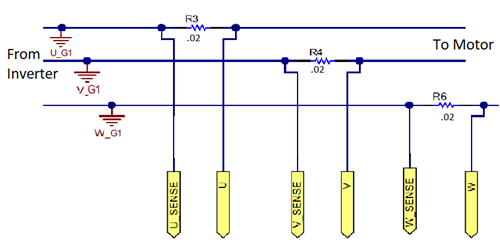

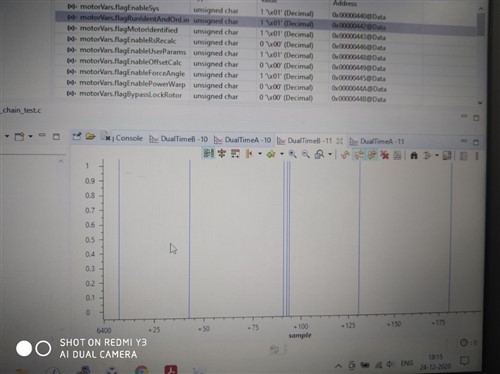

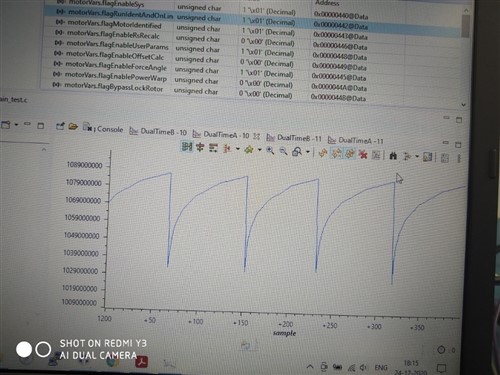

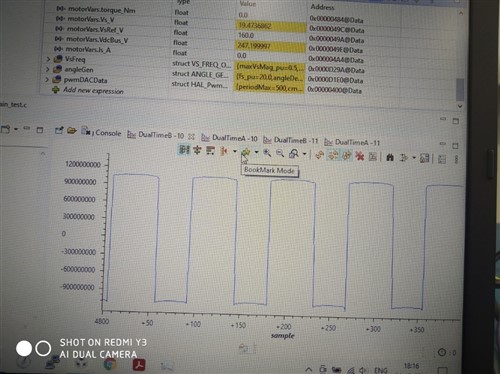

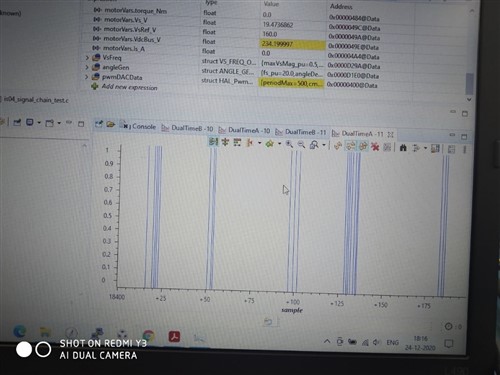

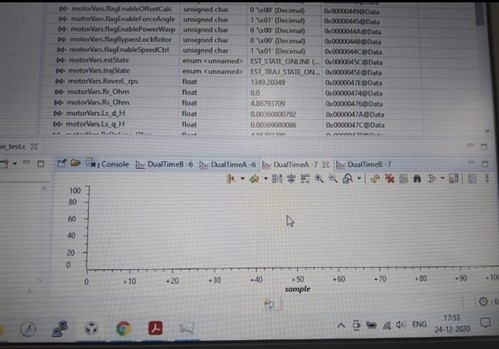

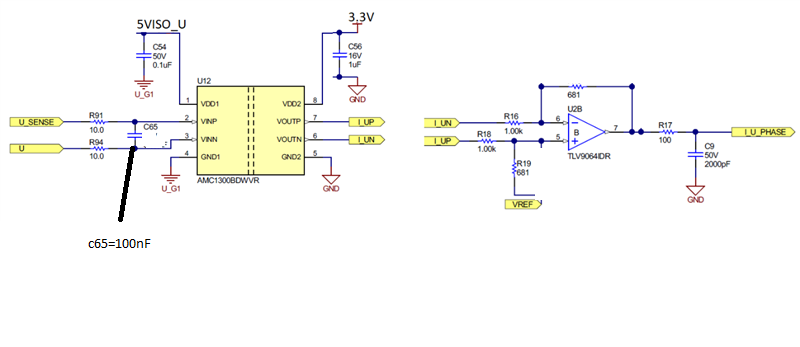

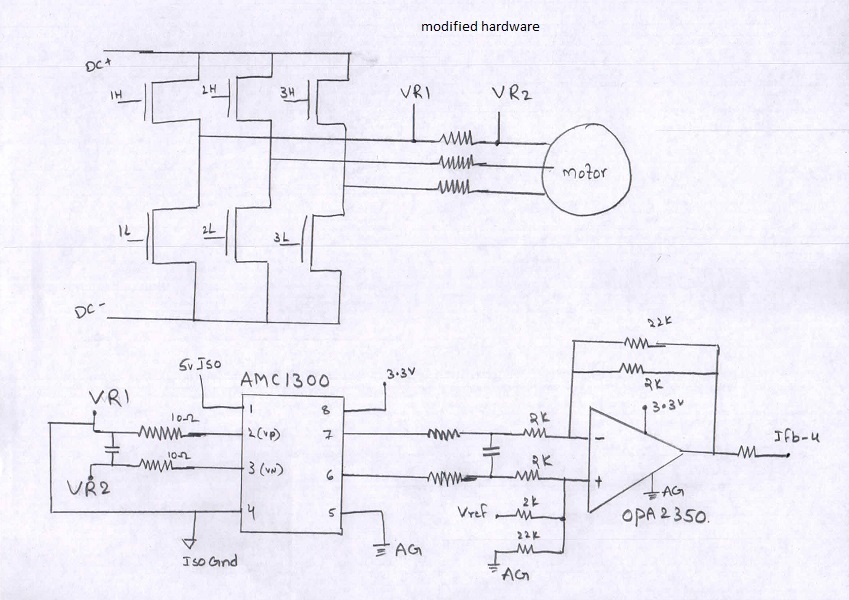

We could control motor with TMDSHVMTRINSPIN development kit, TMS320F280049C control card and TMDSADAP180TO100, by loading the example projects presented in below path "C:\ti\c2000\C2000Ware_MotorControl_SDK_3_00_01_00\solutions\tmdshvmtrinspin\f28004x\ccs\sensorless_foc ". Now we are going to run the motor by changing the hardware as shown in below image( modified hardware) we sense the current at inline resistors.

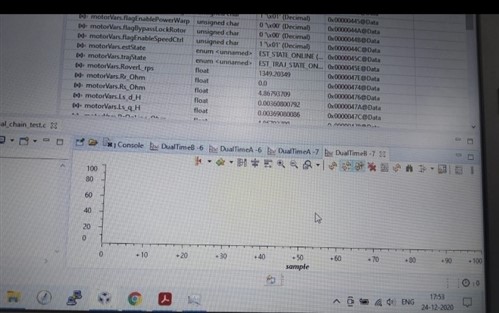

1. We disconnected R14,R16,R17,R33,R34,R41 on HV-kit and we connect like below image (modified hardware), Is this HW good for testing?

2. I understand from Steve Lim‘s answer no code change is needed. (Refer to 28/Sep post by Steve Lim: https://e2e.ti.com/support/microcontrollers/c2000/f/171/p/940417/3487721#3487721).

"Both currents are same motor winding current at zero vector. So there is nothing you have to change the code if you keep same current sensing polarity".

We have a doubt on Keeping current sensing polarity. Can you please help us understand how to do that?

3. With the new HW changes, shall I start from Lab1 again?

Thank you