Part Number: TMS320F28388D

When testing the demo of adc_ex1_soc_software that comes with it

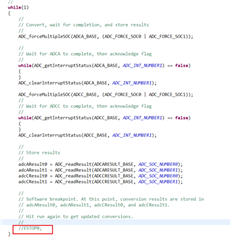

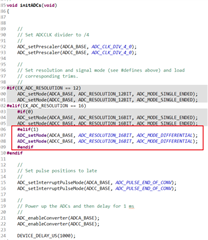

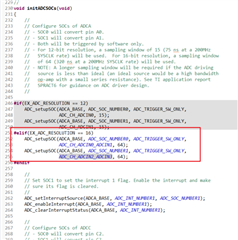

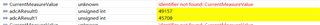

When F28388D multi-channel ADC performs differential and single sampling, give ADCA 1 channel 1.5V voltage, 2 channels are not connected to the voltage, and left open, the values of channels 1, 2 are basically the same. But it is normal for single-ended sampling How do I set it up? The following figure shows the process of changing the single-ended sampling in the demo to differential sampling, and the final test result.