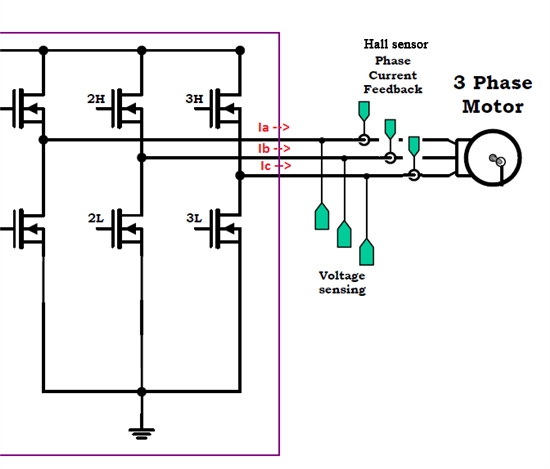

I do my board according to DRV8301-69M-KIT.The only difference is that I use hall sensor for current sampling.As shown.The measuring range of hall sensor is ± 833.33A.

Now I encounter some problems.The parameters of my BLDC motor can be identified well on DRV8301-69M-KIT,but something unusual happened on my board.The motor produce a strong shock and a harsh noise in lab02a.

As I know, the current(100Hz) is injected in order to calculate current controller gains in lab02a.So I see waveform of this current.I was shocked the current was too large... As shown

Current frequency is 100Hz,but peak-to-peak value = 74A. I do not know the reason.

My motor parameters:

Rated voltage:48V

Pole pairs:4

Rated power: 1KW

motorware:13

CCS:5.5

compiler:6.2.6

user.h:6013.user.h