Other Parts Discussed in Thread: UNIFLASH

Tool/software:

Hello,

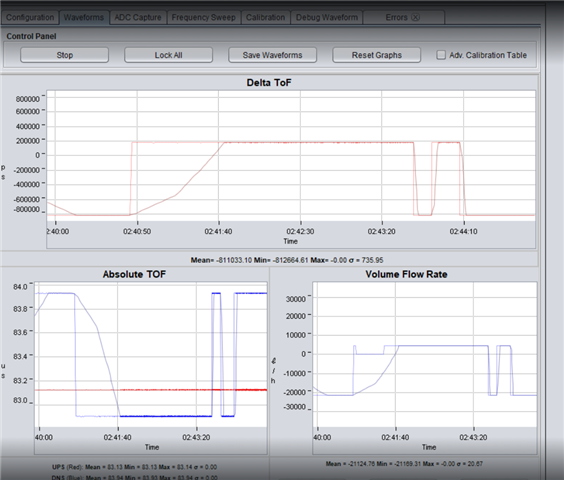

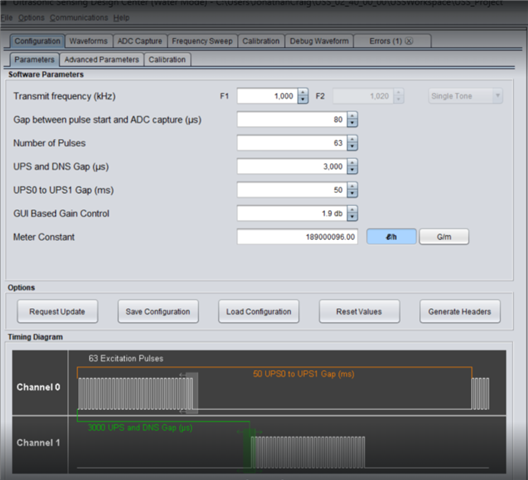

I have recently been testing the EVM430FR6047 eval kit on a water flow meter test rig. After calibration with the default values the water meter displays the same values as the reference flowmeter. However, when i attempt to tune parameters it can cause the flowmeter to change from the correct value to -21124 L/h.

The only way for me to fix the issue is to reset the device - > update the settings then enter the calibrated meter constant then update the settings again.

If i change parameters such as increasing the number of pulses or changing the gain then i get -21124 L/h again. The GUI feels very temperamental. Some values i have used in the past that worked occasionally do not.

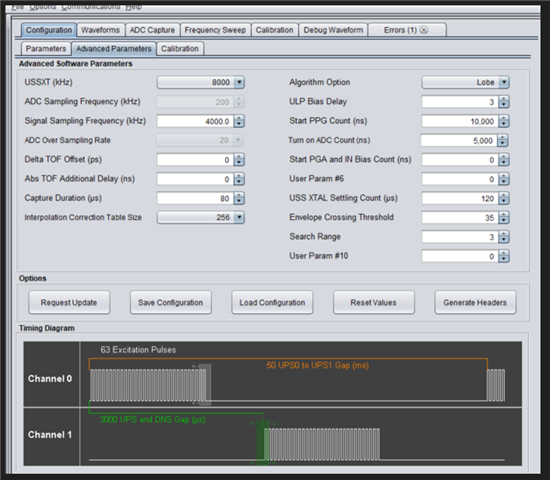

Can anyone help me understand the relationship between the parameters on the configuration tab?

Any help is appreciated.

An example of a broken waveform: