Hi,

When I make proximity design with Captivate Studio design centre. I confirm the created code has been programmed in MCU with latest parameters. I have issue as follows that I think something should go wrong with my parameter setting:

design centre. I confirm the created code has been programmed in MCU with latest parameters. I have issue as follows that I think something should go wrong with my parameter setting:

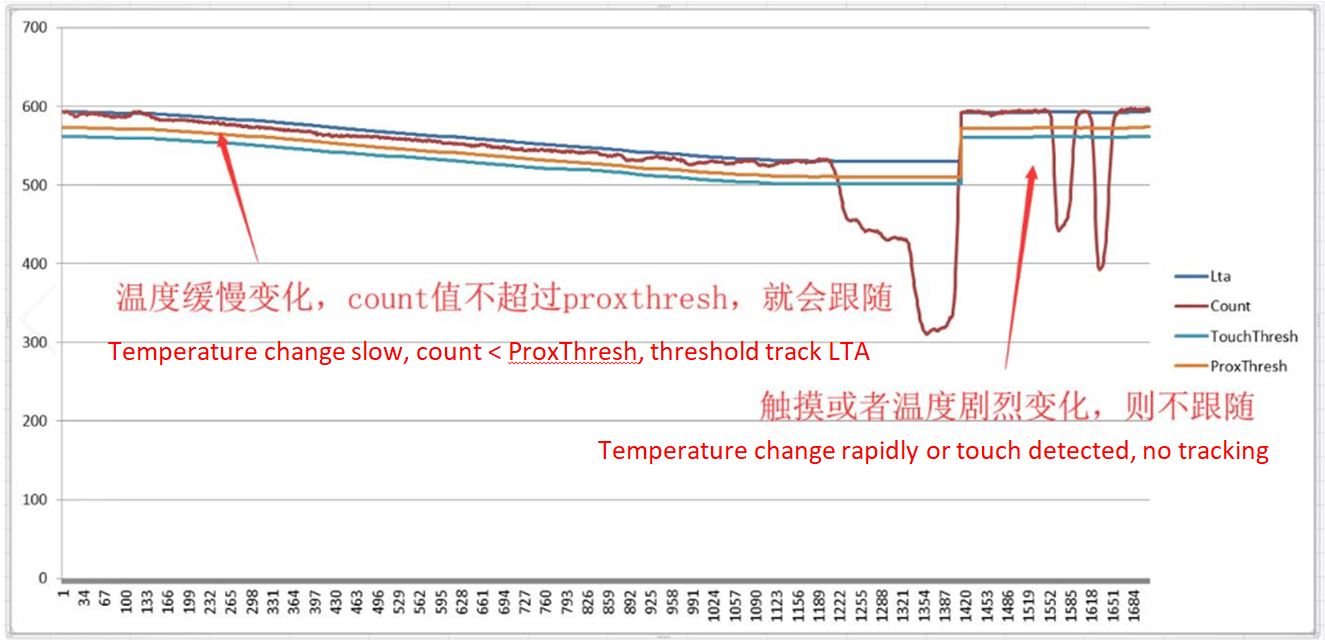

1. Max Count Error always happens, even if I changed different electrode. I confirm HW connection is all right and I can check variation of count data with trend I expected;

2. SNR does not work after pressing'Measure SNR', always grey without any feedback;

3. The count data sometimes normal with tiny floating means it's alive but some times just a stable value unless touch electrode with a drop , no environment changed during the whole process.

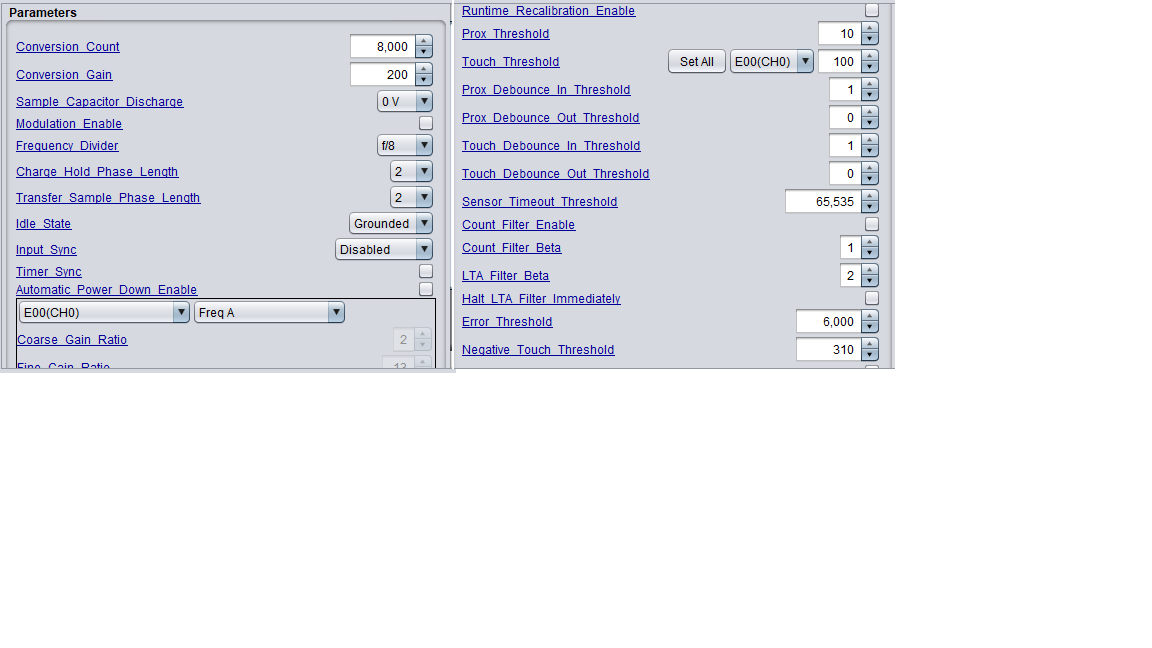

I have no reference regarding the parameter setting, I set the conversion count very high with high conversion Gain with purpose of large increase for delta of count before and after proximity happens and can be enough margin to distinguish out of background noise.Could you please give me some suggestions for fixing these issue?Thanks! Attached is my parameter setting.

B.R

FANS