Tool/software: Code Composer Studio

Good day admin,

Im using MSP430FR2633 (as I2C master) to control a carbon dioxide (CO2) sensor, SCD30 by Sensirion. All technical information on the sensor can be found on the link below:

https://www.sensirion.com/en/download-center/carbon-dioxide-sensors-co2/co2-sensor/

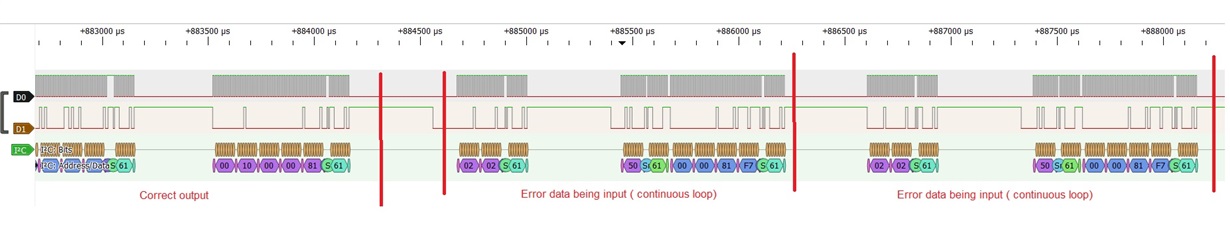

When I use the MSP430FR2633 I2c resource example code for the sensor, only 1 cycle of reading can be captured and then the I2C fail to continue function even though its in the while loop. I will have to keep reseting the MCU on the Dev board to repeat the single cycle of reading and even so, its not a guaranteed any data can be read. Not too sure if there are any issues in the buffer.

For reference, the TI I2C example code is as follows: msp430fr243x_eusci_i2c_standard_master.c, Author: Nima Eskandari and Ryan Meredith, January 2018 , Built with CCS V7.3

I would like to know if I made any mistake or miss out something in my following main.c code on the I2C portion:

I2C initialization portion:

void initGPIO()

{

// Configure GPIO

LED_OUT &= ~(LED0_PIN | LED1_PIN); // P1 setup for LED & reset output

LED_DIR |= (LED0_PIN | LED1_PIN);

// I2C pins

P1SEL0 |= BIT2 | BIT3;

P1SEL1 &= ~(BIT2 | BIT3);

// Disable the GPIO power-on default high-impedance mode to activate

// previously configured port settings

PM5CTL0 &= ~LOCKLPM5;

}

void initClockTo16MHz()

{

// Configure one FRAM waitstate as required by the device datasheet for MCLK

// operation beyond 8MHz _before_ configuring the clock system.

FRCTL0 = FRCTLPW | NWAITS_1;

// Clock System Setup

__bis_SR_register(SCG0); // disable FLL

CSCTL3 |= SELREF__REFOCLK; // Set REFO as FLL reference source

CSCTL0 = 0; // clear DCO and MOD registers

CSCTL1 &= ~(DCORSEL_7); // Clear DCO frequency select bits first

CSCTL1 |= DCORSEL_5; // Set DCO = 16MHz

CSCTL2 = FLLD_0 + 487; // DCOCLKDIV = 16MHz

__delay_cycles(3);

__bic_SR_register(SCG0); // enable FLL

while(CSCTL7 & (FLLUNLOCK0 | FLLUNLOCK1)); // FLL locked

}

//-----------------------------------------------------------------------------

void SCD30_Init() /* -- adapt the init for your uC -- */

{

// init I2C

UCB0CTLW0 = UCSWRST; // Enable SW reset

UCB0CTLW0 |= UCMODE_3 | UCMST | UCSSEL__SMCLK | UCSYNC; // I2C master mode, SMCLK

UCB0BRW = 160; // fSCL = SMCLK/160 = ~100kHz

UCB0I2CSA = SLAVE_ADDR; // Slave Address

UCB0CTLW0 &= ~UCSWRST; // Clear SW reset, resume operation

UCB0IE |= UCNACKIE;

//SCD30_SetI2cAdr(i2cAddress);

//SCD30_SetI2cTimeout(timeoutI2c);

}

Interrupt portion:

#if defined(__TI_COMPILER_VERSION__) || defined(__IAR_SYSTEMS_ICC__)

#pragma vector = USCI_B0_VECTOR

__interrupt void USCI_B0_ISR(void)

#elif defined(__GNUC__)

void __attribute__ ((interrupt(USCI_B0_VECTOR))) USCI_B0_ISR (void)

#else

#error Compiler not supported!

#endif

{

//Must read from UCB0RXBUF

uint8_t rx_val = 0;

switch(__even_in_range(UCB0IV, USCI_I2C_UCBIT9IFG))

{

case USCI_NONE: break; // Vector 0: No interrupts

case USCI_I2C_UCALIFG: break; // Vector 2: ALIFG

case USCI_I2C_UCNACKIFG: // Vector 4: NACKIFG

break;

case USCI_I2C_UCSTTIFG: break; // Vector 6: STTIFG

case USCI_I2C_UCSTPIFG: break; // Vector 8: STPIFG

case USCI_I2C_UCRXIFG3: break; // Vector 10: RXIFG3

case USCI_I2C_UCTXIFG3: break; // Vector 12: TXIFG3

case USCI_I2C_UCRXIFG2: break; // Vector 14: RXIFG2

case USCI_I2C_UCTXIFG2: break; // Vector 16: TXIFG2

case USCI_I2C_UCRXIFG1: break; // Vector 18: RXIFG1

case USCI_I2C_UCTXIFG1: break; // Vector 20: TXIFG1

case USCI_I2C_UCBCNTIFG:break;

case USCI_I2C_UCCLTOIFG: break;

case USCI_I2C_UCBIT9IFG: break;

case USCI_I2C_UCRXIFG0: // Vector 22: RXIFG0

rx_val = UCB0RXBUF;

if (RXByteCtr)

{

ReceiveBuffer[ReceiveIndex++] = rx_val;

RXByteCtr--;

}

if (RXByteCtr == 1)

{

UCB0CTLW0 |= UCTXSTP;

}

else if (RXByteCtr == 0)

{

UCB0IE &= ~UCRXIE;

MasterMode = IDLE_MODE;

__bic_SR_register_on_exit(CPUOFF); // Exit LPM0

}

break;

case USCI_I2C_UCTXIFG0: // Vector 24: TXIFG0

switch (MasterMode)

{

case TX_REG_ADDRESS_MODE:

UCB0TXBUF = TransmitRegAddr;

if (RXByteCtr)

MasterMode = SWITCH_TO_RX_MODE; // Need to start receiving now

else

MasterMode = TX_DATA_MODE; // Continue to transmision with the data in Transmit Buffer

break;

case SWITCH_TO_RX_MODE:

UCB0IE |= UCRXIE; // Enable RX interrupt

UCB0IE &= ~UCTXIE; // Disable TX interrupt

UCB0CTLW0 &= ~UCTR; // Switch to receiver

MasterMode = RX_DATA_MODE; // State state is to receive data

UCB0CTLW0 |= UCTXSTT; // Send repeated start

if (RXByteCtr == 1)

{

//Must send stop since this is the N-1 byte

while((UCB0CTLW0 & UCTXSTT));

UCB0CTLW0 |= UCTXSTP; // Send stop condition

}

break;

case TX_DATA_MODE:

if (TXByteCtr)

{

UCB0TXBUF = TransmitBuffer[TransmitIndex++];

TXByteCtr--;

}

else

{

//Done with transmission

UCB0CTLW0 |= UCTXSTP; // Send stop condition

MasterMode = IDLE_MODE;

UCB0IE &= ~UCTXIE; // disable TX interrupt

__bic_SR_register_on_exit(CPUOFF); // Exit LPM0

}

break;

default:

__no_operation();

break;

}

break;

default: break;

}

}

I2C read and write functions:

I2C_Mode I2C_Master_ReadReg(uint8_t dev_addr, uint8_t reg_addr, uint8_t count)

{

/* Initialize state machine */

MasterMode = TX_REG_ADDRESS_MODE;

TransmitRegAddr = reg_addr;

RXByteCtr = count;

TXByteCtr = 0;

ReceiveIndex = 0;

TransmitIndex = 0;

/* Initialize slave address and interrupts */

UCB0I2CSA = dev_addr;

UCB0IFG &= ~(UCTXIFG + UCRXIFG); // Clear any pending interrupts

UCB0IE &= ~UCRXIE; // Disable RX interrupt

UCB0IE |= UCTXIE; // Enable TX interrupt

UCB0CTLW0 |= UCTR + UCTXSTT; // I2C TX, start condition

__bis_SR_register(LPM0_bits + GIE); // Enter LPM0 w/ interrupts

return MasterMode;

}

I2C_Mode I2C_Master_WriteReg(uint8_t dev_addr, uint8_t reg_addr, uint8_t *reg_data, uint8_t count)

{

/* Initialize state machine */

MasterMode = TX_REG_ADDRESS_MODE;

TransmitRegAddr = reg_addr;

//Copy register data to TransmitBuffer

CopyArray(reg_data, TransmitBuffer, count);

TXByteCtr = count;

RXByteCtr = 0;

ReceiveIndex = 0;

TransmitIndex = 0;

/* Initialize slave address and interrupts */

UCB0I2CSA = dev_addr;

UCB0IFG &= ~(UCTXIFG + UCRXIFG); // Clear any pending interrupts

UCB0IE &= ~UCRXIE; // Disable RX interrupt

UCB0IE |= UCTXIE; // Enable TX interrupt

UCB0CTLW0 |= UCTR + UCTXSTT; // I2C TX, start condition

__bis_SR_register(LPM0_bits + GIE); // Enter LPM0 w/ interrupts

return MasterMode;

}

void CopyArray(uint8_t *source, uint8_t *dest, uint8_t count)

{

uint8_t copyIndex = 0;

for (copyIndex = 0; copyIndex < count; copyIndex++)

{

dest[copyIndex] = source[copyIndex];

}

}

Thank you for your kind assistance in this.

Best regards,

Wyman