Hello All,

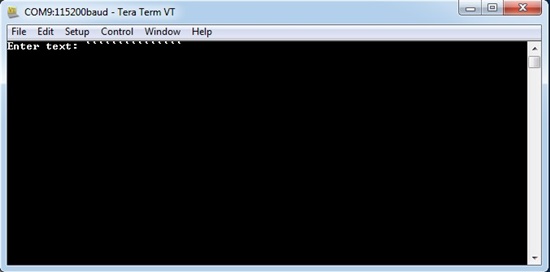

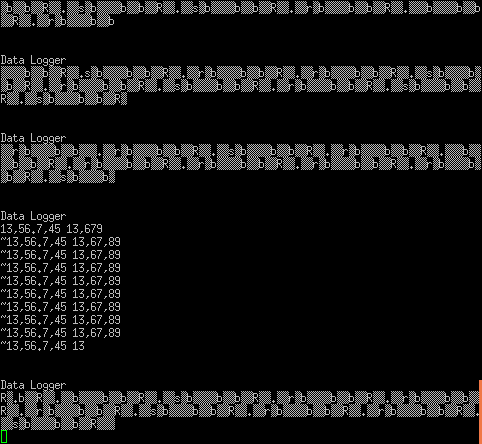

I am using the Launchpad to read serial data from an instrument. Each reading from the instrument is prefixed with the '~' character. I am trying to read this serial input (via UART5). However, I have some trouble parsing this data. Here is the portion of code I am using:

int b=0;

int noofreadingstoaverage5;

while (b<noofreadingstoaverage){

//c=UARTCharGetNonBlocking(UART5_BASE);

c=UARTCharGet(UART5_BASE);

UARTprintf("%c",c); // echo character

if ((c=='~')||(c==126)) {

b++;

UARTprintf("\n%i",b);

}

}

The trouble is the input '~' is not being counted. So b remains 0. How do I fix this?

Thanks.

Mike