Other Parts Discussed in Thread: DRV8353, DRV8350

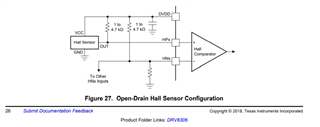

This is the second Issue (First issue resolved from TI ) which i have found while using the DRV8306 after 6 months. While testing i found that if one of the Hall sensor Input Either HALL A, B or C is disconnected and the motor start operating (Ideally if one of the hall sensor is not changing state from logic 1 to 0 and vice versa over one period of commutation the IC Should give NFAULT INDICATION and stop commutation but this does not happen and the motor continues to operate.) If the hall sensor is then again connected the hall sensor state at IC pin is not changing (Please Note: The hall sensor of the motor used for Testing are perfectly fine and proper voltage level of 3V3 is observed when tested Seperately.

Since the HALL A, B or C input pin was constantly held on ground state i.e. Logic 0, I Checked the Resistance between the pin and Ground and I Found that the Resistance is 68 ohm. When I tested with a fresh working piece in which proper waveform was observed on all 3 HALL Pin, I Found that the Resistance between ground and pin is about 25K ohm. Again when i conducted the same test by disconnecting hall sensor. The motor operated and after turning off the power i checked the resistance THE RESISTANCE DROPPED TO 68 OHM. This is a serious problem which i am facing in production. The hall sensor getting disconnected due to loose harness and causing damage to the Hall sensor Pin is a Serious Issue.

I Request you to please provide a solution to solve this problem ASAP. Once the pin is Damaged the IC is of no use since it does not generate proper Hall sensor waveform.