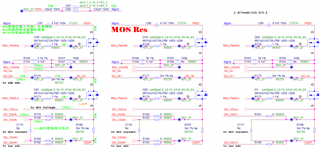

The PVDD1=PVDD2 is 25V or lower.

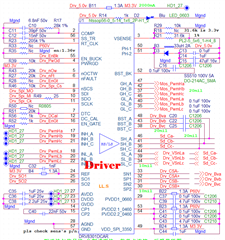

At first time, the drv8301 seems to work ok at first power up.

The pwm input is ok, and the pwm output is ok. And the Motor is rotating.

But suddenly, the drv8301 seems to damage.

The nFault is always low, (after re-power up or dis/enable the En_Gate )

And the GVDD is low about 2.0V.

The DVDD,AVDD seems to OK.

How can I to do to check the drv8301 is ok or not ?