Other Parts Discussed in Thread: TMS320F280049C, DRV8316, LAUNCHXL-F280049C, , DRV8316REVM, DRV8320

Hi Team,

My customer is surveying our DRV8320R, below are some questions need you reply!

- Does DRV8320R must need Hall sensor to determine rotor position for drive ?

- Does DRV8320R feature fast / slow / mixed decay recirculation mode during the braking ?

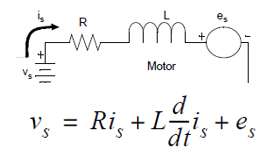

- When DRV8320RS brakes, how's the BEMF (back EMF) impact the circuit? Should add any protection or not?

- When DRV8320RS brakes, the energy in motor go through like below right ? How customer judge need to add a Active Brake Circuit or not in their design ?

Thank you!

Kai