Other Parts Discussed in Thread: MCT8316A, DRV11873,

Hi,

I am designing a large air-gap (more than 10mm or about half inch), low speed (200 rpm at most) axial flux BLDC motor for a specific application. Previously I have tried to use DRV11873 to drive my motor. The startup was extremely fast and reliable. But unfortunately DRV11873 was unable to start my motor under the heaviest load it may encounter. So I switched to MCT8316A, which appears to be the highest current/power BLDC driver TI is offering.

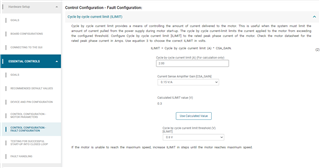

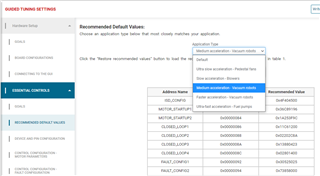

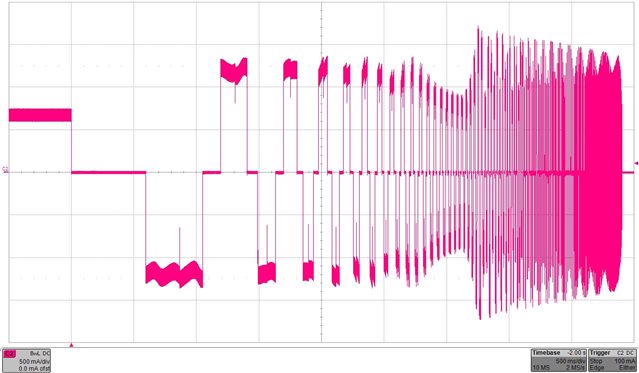

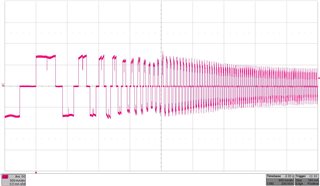

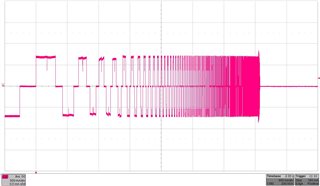

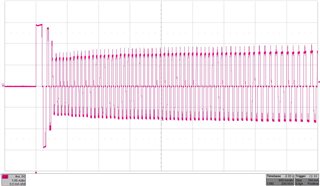

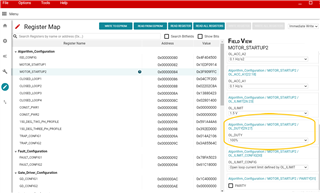

However, MCT8316AEVM was unable to start my motor reliably. My motor just vibrates and makes weird noise without spinning unless I set the open and close loop acceleration coefficients (A1, A2, CL_ACC) all the way to almost the lowest setting. When I got my motor to run by doing that, the motor accelerates extremely slow, taking up to 30 seconds to reach full speed and sometimes the starting is still unsuccessful. Now I am testing without adding any load yet. With DRV11873, the startup is almost instant and successful in every attempt under the same condition.

I tried all startup options. Only align and double align seems to work. IPD just trigger a fault. Slow first cycle sometimes works.

For my application, I don't care about torque ripple or acoustic noise. Is there any settings I can try that may improve startup reliability as well as getting a faster startup? Or is there any driver that works similar to DRV11873 but handles higher power/current?

Thank you