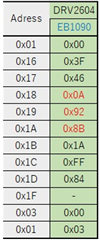

Other Parts Discussed in Thread: DRV2604

Hi Expert,

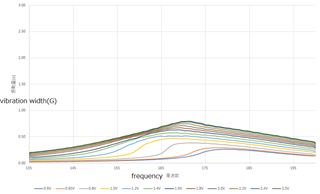

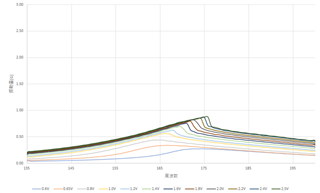

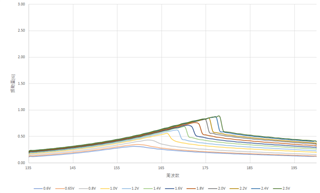

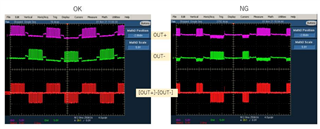

Mt customer have an issue of output waveform.

It is occurred by some motors, They have OK motor and NG motor even if same motor part#. They tried to replace another motor, Then, this issue was improved.

Also this issue have often occurred at low temp condition. (At 0C, 2/6 pcs NG)

Could you please give me your advice for the reason of this waveform?

What motor characteristics depend on this issue?

Thanks

Muk