Other Parts Discussed in Thread: C2000WARE, DAC128S085

Hello

I think, I need some advice, how to do a motor identification .

I have

- LauchXL F280049C

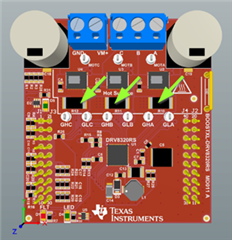

- BoostXL DRV8320RS

- MotorControSDK 3.03.00.00

- instaspin_spruhj1i.pdf

- InstaSPIN Projects and Lab User's guide V1.00.00.00 pdf. Instaspin FOC labs 01-13

- I am able to run / identify a "simple" motor (like a drone motor) successfully by executing LAB05 from C:\ti\C2000Ware_MotorControl_SDK_3_03_00_00\solutions\boostxl_drv8320rs\f28004x\ccs\sensorless_foc\is05_motor_id_eabi

- I reduced the Voltage Range and the Current Range of BoostXL-DRV8320 to 29V and 6A and modified user.h accordingly (works fine)

Very good so far.

Now I need to identify "our" motor. It has some "tricky" parameters

- RS = 6.67 Ohms

- ROverL = 31,4

- flux Volt/Hz = 0,007

- 1 pole pair

- operating speed 9000 RPM -> 33000 RPM = 150Hz -> 550 Hz

- CANNOT be detached from load (it is a pump)

- has VERY little inertia

- has a high startup torque

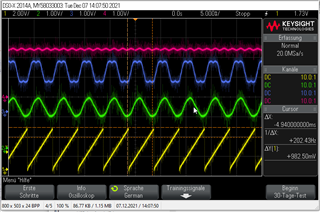

I was able to run "motor identify Lab exercise" up until "EST_STATE_RAMPUP". (Operating-Point 150Hz). Motor is running. A Value for Flux Volt/Hz is measured during rampup and it is fairly stable.

When finished, the motor immediately stops. I cannot tell, if this is during "EST_STATE_CONSTSPEED" or during "EST_STATE_RATEDFLUX_OL" or "EST_STATE_RATEDFLUX"

What options do I have to identify Lq and Ld manually?

Is there a more detailed description, what the estimator is doing during motor identification and to find out, why it stopped immediately after ramp-up? Is there a way to stop the estimator at a certain state to find out, which step is causing the problem?

Furthermore:

If I want to run the motor (if identified) I need to do a open-loop startup until the frequency is e.g. 150Hz. How do I do that? Is there a more detailed description, how to tweak the startup process?

In addition: I find it quite difficult to understand, how the flag "userParams.flag_bypassMotorId" is passed to the estimator. How does the estimator know, that it does not need to run a motor identification?

Thank you for your help

Johannes