Hi Experts,

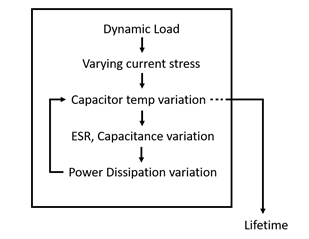

I'm trying to figure out how to size DC-Link capacitance for motor controller. Most of the literature considers current and voltage ripple to get value of C. However, I'm looking for practical design, i.e. considering a dynamic loads, ESR, temp and lifetime variations. A graphical representation of my query -

Any references/papers/videos/practical designs would be appreciated. How is capacitor sizing done in the industry? Just a preliminary analysis showed that theoretical approach might get convoluted. So I was wondering what are the widespread practices in the industry and the success of designs based on these practices?