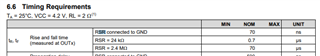

Having a problem with DRV8850. Often it will not deliver adequate power to the motor. If we remove power from the chip and try again, it works. Not sure if we are missing something.

Its a fairly high current application, but within the specifications.

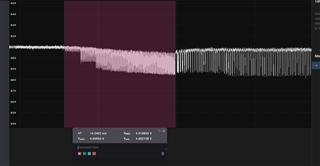

We put a logic analyzer on the battery and can see about a 20khz oscillation in the output. Looks like the motor output has about a 20% on duty cycle, even with 100% PWM.