Hello,

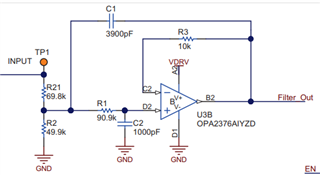

I am planning to use DRV2700 in my project to drive a piezoelectric actuator.

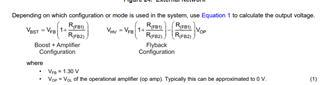

The actuator needs DC voltage from 0 to 150 VDC, the output voltage shall be variable from 0 to 150VDC insteps of 1 VDC.

The actuator has a capacitance of 26uF. Can the flyback configuration using DRV270 be used for the above application.

Regards,

Arun R