TI’s DRV10x family of motor drivers includes integrated MOSFET, and integrated control functionality to spin a 3-Phase BLDC motor without an external microcontroller. DRV10x devices minimize noise and vibration with true and accurate and true 180° “sinusoidal” algorithms.

One of the design challenges in DRV10x is to minimize startup time. Startup time is the time taken for the motor to reach the target speed from zero speed. Applications such as blowers, pumps require faster startup time. DRV10x provides options to minimize startup time.

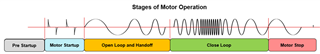

DRV10x operates at multiple stages such as Pre-startup, Motor startup, Open loop, Closed loop and Motor stop. Tuning is involved in each stages of operation (except Motor stop) to minimize startup time.

Pre-Startup:

During the Pre-startup stage, Initial speed detect (ISD) function is used to identify the initial condition of the motor. If ISD is disabled, device will assume the initial condition of the motor to be stationary. To minimize startup time, it is recommended to disable ISD.

Motor Startup:

DRV10x devices provide two startup methods.

- Align

- Initial Position Detect (IPD)

To minimize startup time, it is recommended to choose IPD as the startup method. Follow below recommendations to minimize IPD startup time.

- Set IPD current threshold to rated current of the motor.

- Set IPD Clock frequency to maximum value.

Open loop and Handoff:

After completing the motor initialization with either align or IPD, the DRV10x device begins to accelerate the motor. This acceleration is accomplished by applying a voltage determined by the open-loop current setting. Follow below recommendations to minimize startup time in open loop.

- Set the open loop current limit close to rated current of the motor.

- Set open loop current rate to maximum value.

- Increase Open loop acceleration coefficients A1 and A2.

- Set the open to closed loop threshold to a minimum value where the device does not trigger “Abnormal BEMF constant” fault.

Closed loop:

In closed loop operation, the DRV10x devices continuously sample the current in the U phase of the motor and uses this information to estimate the BEMF voltage that is present. The drive state of the motor is controlled based on the estimated BEMF voltage. Follow below recommendation to minimize startup time in closed loop.

- Increase closed loop acceleration.