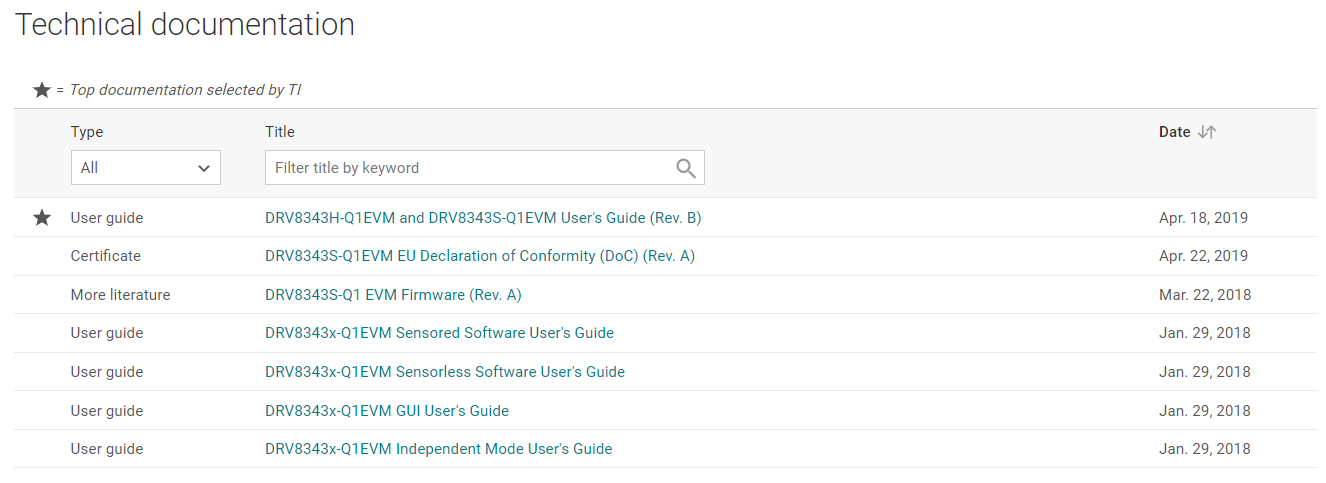

Other Parts Discussed in Thread: DRV8343S-Q1EVM, DRV8343-Q1, MSP430F5529

Hi experts,

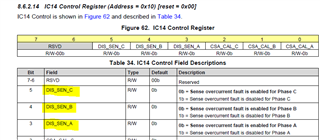

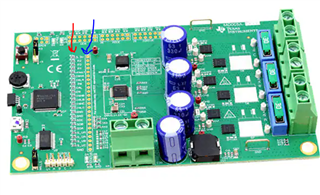

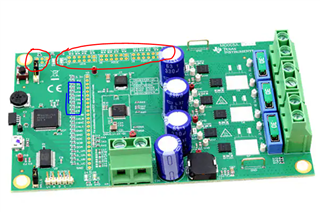

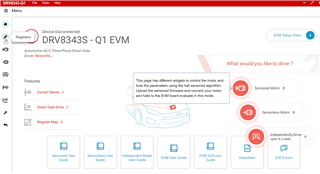

I wonder know if I can use this EVM board to test DRV8340H?

Like directly replace DRV8343H by DRV8340H.

What features do I need to care?

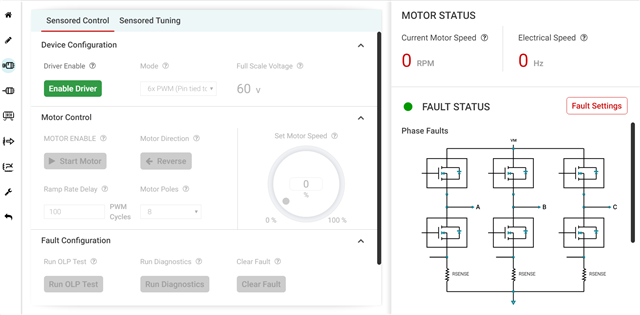

Otherwise, I saw there is a hall sensor pin in EVM.

Does it have hall sensor soldering space on EVM?

How could I accomplish testing by DRV8340H+Hall sensor on DRV8343H-Q1EVM?

BR,

Thank you.