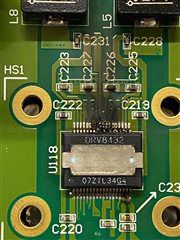

Part Number: DRV8432

Hi TI support.

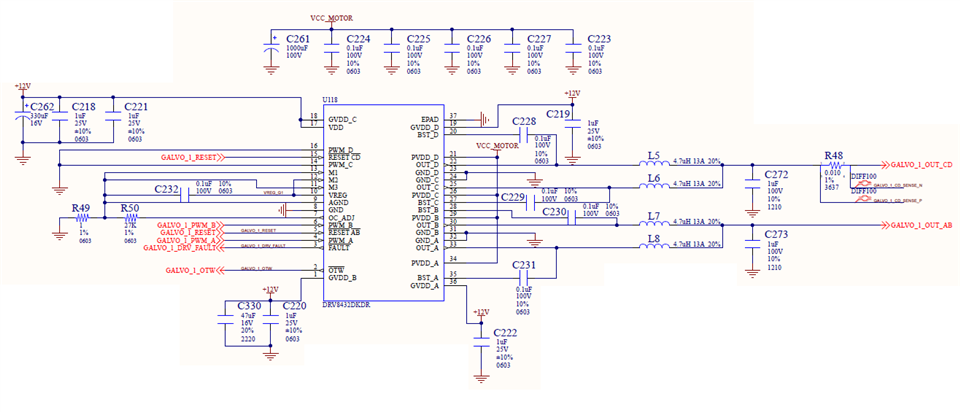

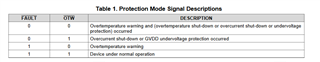

I use DRV8432 to drive motor 0.24mH, 1ohm coil. My configuration:

- Parallel Full Bridge Mode Operation.

- 500KHz PWM frequency.

- 4.7uH inductors installed on each output before connection two channels together.

- 2.2uf capacitors connected to ground from these connection points (for filtering out PWM frequency).

Is it OK to have these capacitors? No such capacitors in application examples to drive inductive load in the data sheet. Such capacitors shown for non-motor related applications (for example, resistive load or dc output).

Can those capacitors be the reason for DRV8432 burning?

Thanks,

Sergey