Other Parts Discussed in Thread: MCF8316A

Hi Team,

Good day!

I have posted the customer's below and kindl plesae help us check.

I am using your DRV10974 to drive a 14-pole motor. The motor spins well but the speed resolution is too low (0.2%). Which controller would be suitable?

This answers the question about the 14-pole motor. However my concern is the speed-control. The DRV10974 has an internal 9 bit ADC. It converts the PWM-signal into an analog voltage which is then converted into a digital signal – via the 9-bit ADC – which then controls the motor-speed. Correct? When I increase the PWM-value in e.g. 0.1% steps either nothing happens or the speed jumps by 0.2% steps. For our application – chopper-motor for gas-analyzer - we need a very constant speed @ approx. 1100 rpm. Therefore we regulate the speed by adjusting the PWM in 0.1% steps.

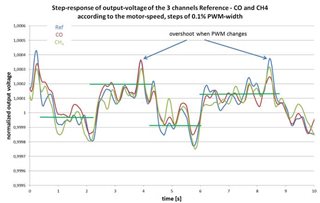

The behavior of the system is as follows

The output voltage changes by approx. 0.025% after changing the PWM by 0.1%, i.e. change of 0.2% in motor-speed.

This doesn’t sound much, but 2% change of the output voltage is equivalent to 3000 ppm gas-concentration. Therefore we see a step of 30 ppm if the channels can’t be compensated by the reference-channel. In the example the channels are quite synchronous which helps. Still we would prefer to have lower jumps, i.e. higher speed-resolution. Do you have a solution?

Best regards,

Jonathan