Other Parts Discussed in Thread: DRV8304

Hello,

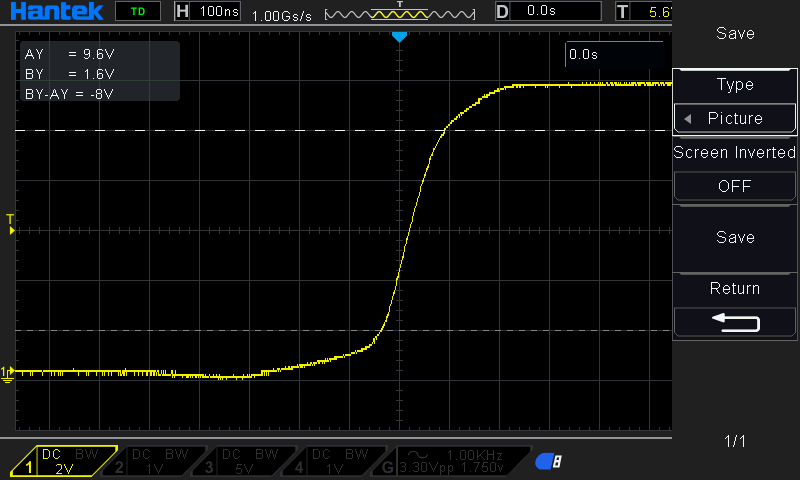

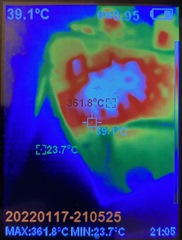

I have experienced a very bad moment, I was working to tune the PID Controller in my algorithm and suddenly I have seen smoke and some lighting on the MOTC Mosfet.

I removed my source and I have seen that Mosfet C and shunt resistor are broken. Mosfets are shorted and shunt resistor is open circuit.

My expectation was that Vds and Vsens process should protect my Mosfets from the disaster.

My supposition is that after a stack overflow the variables with the ADC Data are overwritten and after that the output is very high and creates a short circuit.( maybe a shout through or Dutty cylces around 100% or 0%)

The High and Low Mosfet are both shorted and the board damaged.

Could u explain it? Why Vds protection or Vsens are both not able to protect the Mosfets?

King Regards,

Nikos