Other Parts Discussed in Thread: DRV8350, DRV8306EVM, DRV8332, DRV8312

Dear Team,

we are having an issue with our motor controller design and have run out of ideas on how to resolve it. The gate driver dies very quickly.

We are using a DRV8350FS to control the half-bridges (Vishay SIZ260DT) of a BLDC motor (maxon 70W EC45 402685), the schematics are attached in the google drive link below.

After booting our microcontroller (STM32F373), we configure the DRV8350FSRTVR as shown on page 3 of the schematics. We use a PWM frequency of 32kHz. The configuration seems to work somewhat as the motor successfully starts to rotate. However, after a while (few minutes), the motor controller signals a VCP / VGLS undervoltage lockout fault and gets very hot (far beyond 100 °C for an ambient temperature of 20 °C).

After reaching this point, the fault is signaled constantly, even after rebooting the board (i.e. toggling power supply) and even if the board was unplugged for hours. We also removed the half-bridges to check if the error persists with no load, which it does.

For broken boards, the voltages at VCP / VGLS pins are less than 4V above their reference potentials of VCC / GND. For good boards, voltages are roughly 15V above their reference potentials.

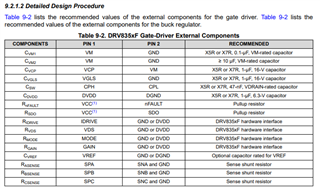

We are constrained by space and thus left out the bypass capacitors of the half bridges, but have followed the other design recommendations as far as we can tell. Can these be the reason that the drivers die so quickly or did we make other mistakes?

The gerber files are attached as well, in case our layout is causing problems.

Any help is greatly appreciated and we will happily provide any further information you require.

Best regards

Mike & Lukas

Attachements: