I have a number of questions about using the DRV10987SPWP driver to drive a 28V motor in a situation with repeated fast accelerations and decelerations:

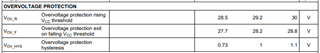

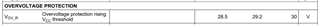

- If the driver Vcc is run at 28V +- 5% (i.e. max of 29.5V), could this cause overvoltage faults in the driver, seeing as the overvoltage protection limit (VOV_R) ranges between 28.5 and 30V in the datasheet?

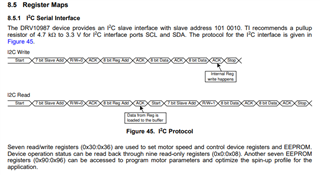

- When the driver reaches an overvoltage or overcurrent fault condition, is communication with the I2C interface still accessible in order to retrieve the fault code?

- When such an error occurs, does the driver recover by itself if the voltage or current drops back down to normal? Or do you need to either send the driver a reset code or do you need to completely power it down?

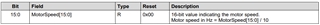

- Are the fault codes in the register persistent, even after the driver comes back to a normal working state?

- If driver faults are raised due to occasional transitory overcurrent or overvoltage spikes and these are ignored and the motor continues to run, could this damage the driver?

Thanks very much.