Dear support team and forum members,

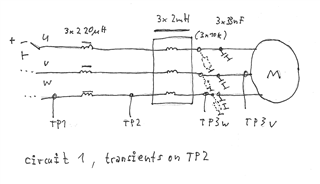

Object of my thread is a circuit which drives a small brushless-motor with low inductivity by a sinus-PWM with 42kHz. The space vector of the TMS320-µC alternates every PWM period from GND to VSS (even when the zero-vector would not alternate in idle mode - the logarithmic concept of EMC would not make the disturbing sent waves significantly smaller). The generated low-frequency is spreaded by a necessary motor-cable from 1 and a half meter length into the air. Furthermore 3 single chokes increase the inductivity of the motor coils to enable feedback of the motor state to be calculated by the µC. At one hand these single chokes, combined with capacitors, act as a low pass but on the other side the low passes can not be sufficiently dimensioned to damp the low-frequency spread-out. Also the lowpass leads to an higher wattles current - warming the single chokes.

About an answer to the following 2 questions I would by happy.

- Is shilding in combination with omitting the low-pass-capacitors better then damping by a common-mode-choke?

- Are there better alternatives to my idea of filtering by the common-mode-choke?

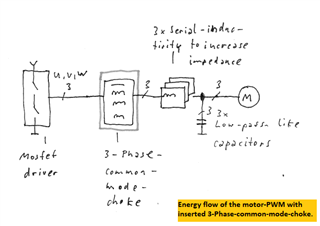

The common-mode-choke solution:

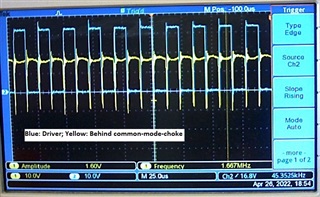

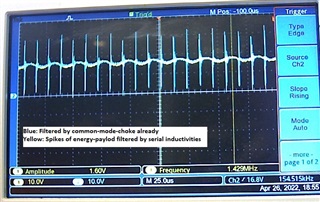

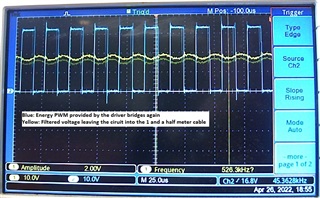

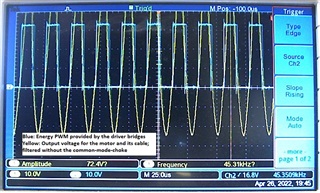

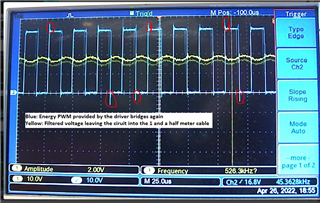

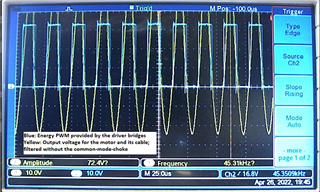

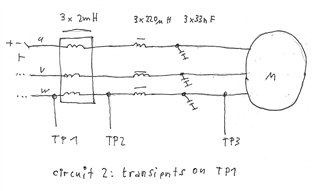

A common-mode-choke is inserted into the energy path which drives the brushless motor. The choke consists of a soft-ferrite ring (see photo) with 3x20 windings and an inductivity of 3x2 mH combined with capacitors of 3x33 nF. Like shown in the screenshots first the common mode choke filters the zero-vector of the sinus-pwm while the 3 single inductivities flatten the payload-spikes. In this guessed approach (not exactly calculated) low-frequency-EMC is damped except some remaining sinus-voltage and also the wattles-idle-current does no longer play a role.

Best regards