Other Parts Discussed in Thread: LAUNCHXL-F28069M, , BOOSTXL-DRV8323RS, MOTORWARE

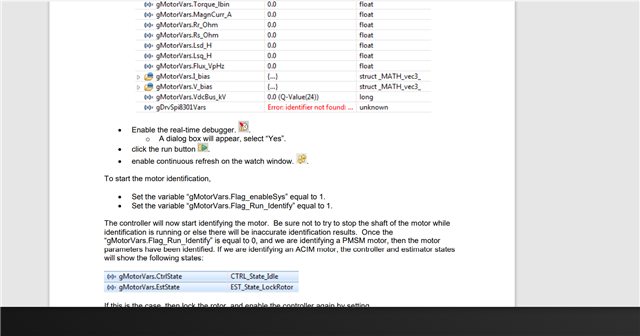

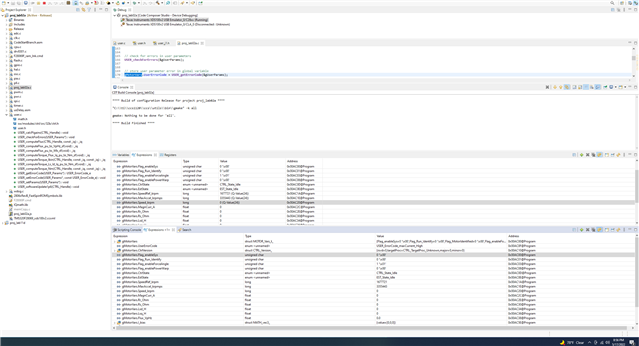

I have a LAUNCHXL-F28069M microcontroller and 2 BOOSTXL-DRV8301 motor drivers. I was running the instaspin lab 10d and entered all of my motor information into the user_mtr_j1.h and user_mtr_j5.h, but had no luck getting my motor spinning. Should this lab work out of the box if you enter your motor info into those files or do you have to modify code in the main function?

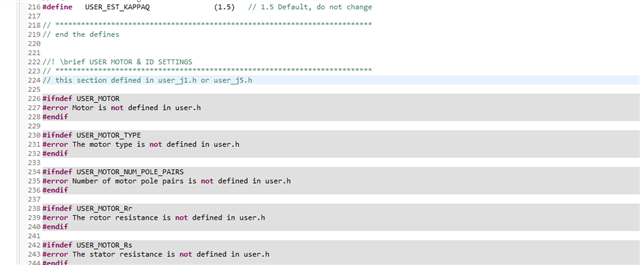

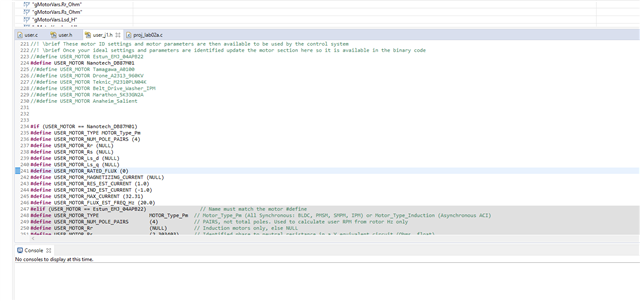

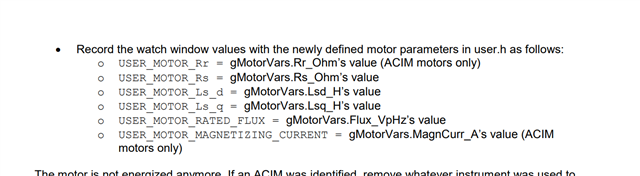

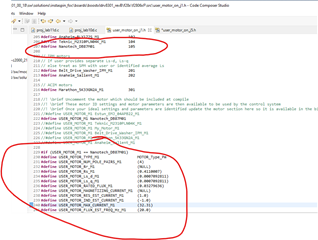

My motor code in the .h files:

Motor Specs:

DB87M01-S.pdf