Other Parts Discussed in Thread: , MCT8316A

Dear Team,

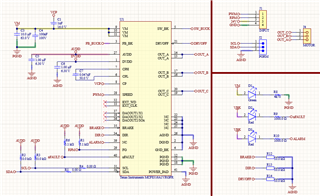

Recently we received MCF8316AEVM from TI. During testing it is found that the algorithm state of the module is changing.

In the datasheet, only ALGORITHM_STATE Register Field Descriptions are provided. I would like to know more about what exactly is happening in each algorithm state.

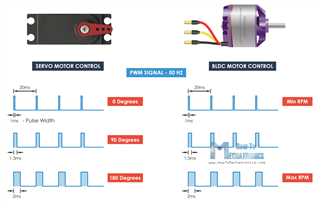

I have another query, can I configure MCF8316A without any controller with PWM input for motor rotation?

Thanks and Regards,

Sujeesh V

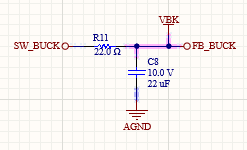

22 Ohm Rbk and 22uF Cbk are used

22 Ohm Rbk and 22uF Cbk are used