Hello,

I'm working on a design using the MCF8316A to spin a custom BLDC motor with a magnetically levitated bearing. Actually, we are still using the pre-production PMCF8316A parts if that makes a difference.

I'm in a strange situation: I have one chip where I successfully ran MPET and burned everything to the EEPROM. That one works great. I want to program another part to perform the same, but now I can't run MPET because something about the first step is causing our magnetic suspension to fail. The suspension isn't TI's problem of course, but it seems like I should be able to replicate the performance of the working part on a second one without running MPET. We need something working in the short term for an important test. I'd also like to increase the ramp rates on the part that is working well, but I don't think I can without overwriting the magic parameters.

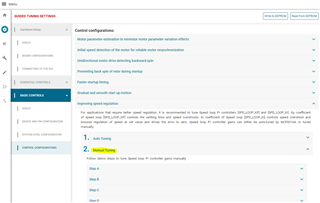

I know how to bypass MPET by manually writing MOTOR_L, MOTOR_BEMF_CONST, and MOTOR_R to the values that I think are right (3.4 ohm, 0.125mH, 2 Ke), then writing SPD_LOOP_KP to 10 and SPD_LOOP_KI to 1 as default values suggested on a previous post on this forum. Running with those parameters does spin the motor, but it draws at least 100mA more than the MPET-tuned parameters saved to the EEPROM. This is with the same chip. My question is: what else is MPET tuning? CURR_LOOP_KP and CURR_LOOP_KI? I tried manually adjusting the current and speed loop KP and KIs in real time, but none of them seem to have an effect on current draw once it's in closed loop aligned state.

One strategy is to try and read out what is saved in the EEPROM so I can write the same values to another part. When I run the GUI (version 1.0.1 since we are using PMCF parts) with the working chip and click "Read from EEPROM", I get a message saying the command was successful, but the MOTOR_L, MOTOR_BEMF_CONST, and MOTOR_R registers still read 0 and the corresponding "Algorithm Variable Status Select" boxes still read "Self Measurement". Am I doing something wrong?

A related question: section 7.3.13 of the datasheet says "The estimated speed loop KP and KI setting can be used as an initial setting only and TI recommends to tune these parameters on application by the user based on the performance requirement.". How exactly do I do this? As far as I can tell, once it's in closed loop aligned state I can change the speed loop KP and KI to any value I want and see no change. Am I missing something?

Thanks,

Mitcham