What are the advantages of using the dedicated speed/brake/dir pins versus controlling the motors using I2C? Our application requires three motors to be controlled from one MCU, and just using I2C for all three motors would reduce the number of wires significantly. Speed of all three motors are controlled by a PID system that self-balances a robot, so the speeds are updated pretty frequently.

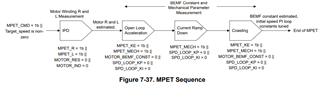

Other question regarding MPET: can this measurement be done once during assembly, or does MPET require to be executed after each reboot? While using the EVM I've noticed that the MPET values sometimes reset to 0 after the EVM is turned off and on.