Hello,

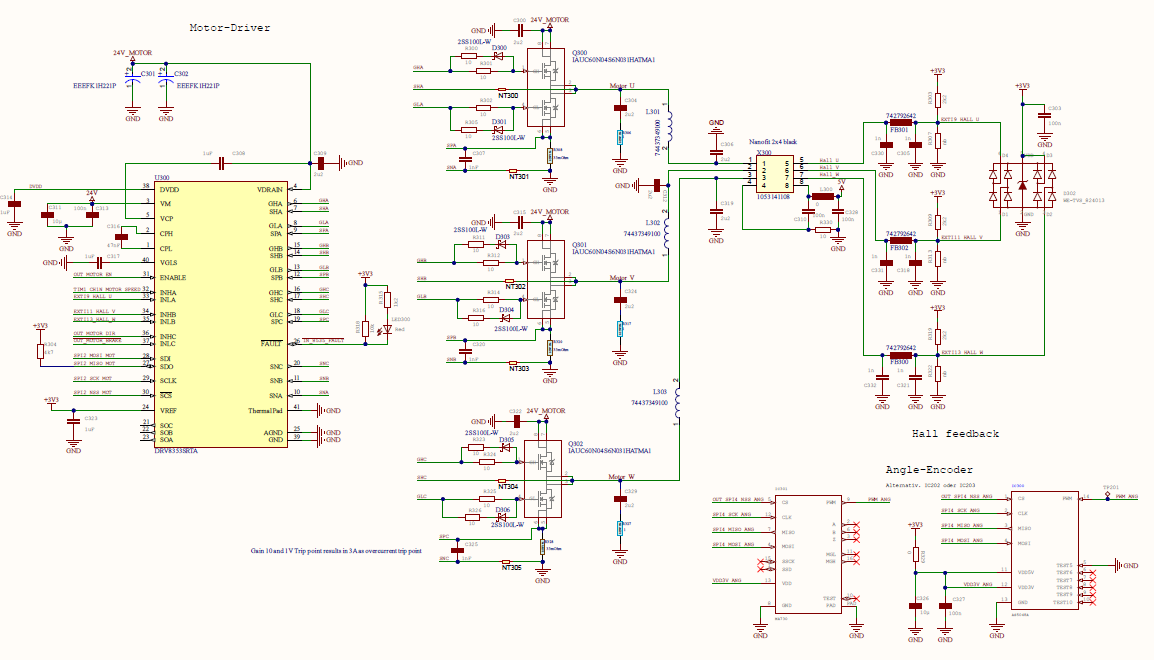

we have a problem with current flow to motor under special conditions.

We use the 1 PWM mode.

We have 2 Problems.

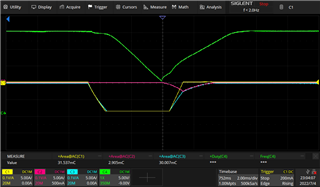

At Startup a high current flow, so that the voltage drops .

Green 24V form the powersupply.

The other signal are the current flow trough the coils.

This happens sometime after enable the motordriver.

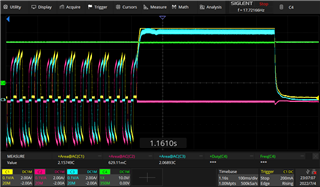

The scond problem is, that if we stop the motor physicaly,

a high dc current is flow through the motor

I think that is because of the simple statemachine inside of the controller.

If there is no more hallsensor signal, it stays in the statmachine within the block commutation.

Is this right?

thanks Andreas