Hi team,

Here's an issue from the customer may need your help:

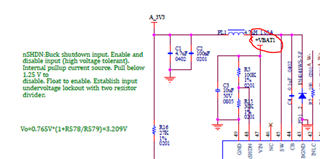

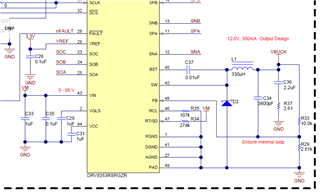

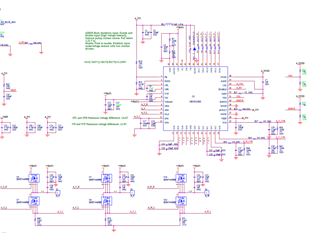

DRV8323RH is used. The MCU is powered using the on-chip internal buck output of 3.3 V and the schematic is as follows.

The 3.3-V waveform is relatively good when the power-up motor is not spinning, while at high speeds the 3.3-V waveform is subject to significant interference (up to 4 V momentary).

The customer would like to know how can the buck output supply included with the DRV8323RH chip be left undisturbed. Can this buck output supply be used by an external MCU? (3.3-V supply output in layout does not overlap adjacent layer to +VBAT1)

Could you help check this case? Thanks.

Best Regards,

Cherry