Hello,

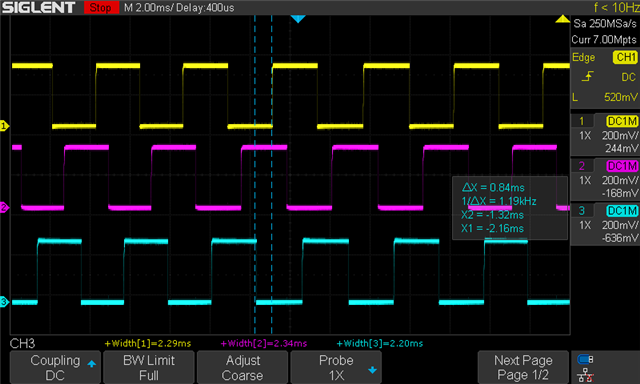

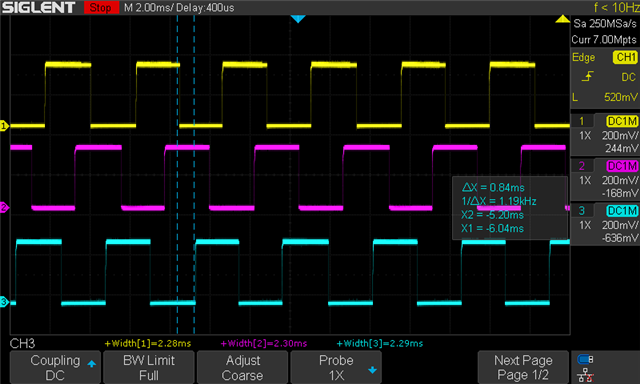

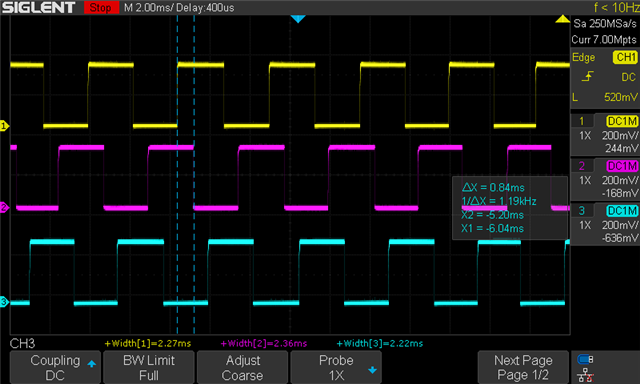

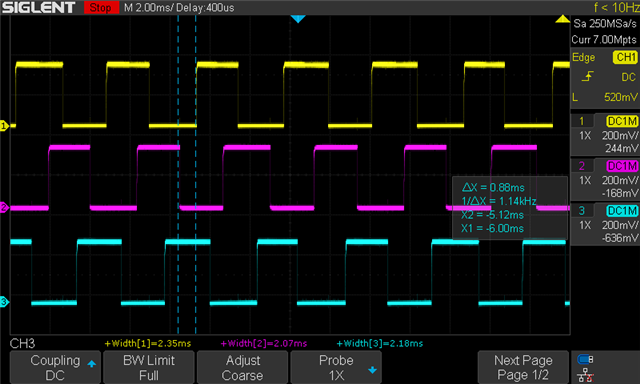

I am working with the MCT8316Z0R (24V on a custom PCB) and have found that different parameters are required for each direction in order to get good performance out of the BLDC motors we are using. Usually this just involves changing ADVANCE_LVL based on which direction the motor is spinning but sometimes different DLY_TARGETs make an impact as well. Changing these parameters based on the direction of the motor can sometimes result in 2-3x efficiency increases. Is this to be expected? We have tested on 5+ different BLDC motors and have found that the need for different parameters in the CW and CCW directions across the board.

Also if you could share any general advice for finding the optimal parameters for the driver under specific load conditions that would be very helpful. Currently we are just using a brute force search trying to maximize rpm / current draw.

Thanks