Hello TI - Team,

we have a problem with a motordriver that we have designed.

We are driving 2 x 24v @ 15A linear actuators with integrated hall sensors. Those intergrated hallsensors provide us with a 5v squarewave feedback which we use to sync the movement between those actuators.

Our micro contoller is an Ardunino RP2040 - we provide a 3v - 1kHz PWM signal to IN1/IN2 for forward drive and reverse polarity. The % of the duty cycle is used to reduce or increase the speed of the actuators to keep them in sync.

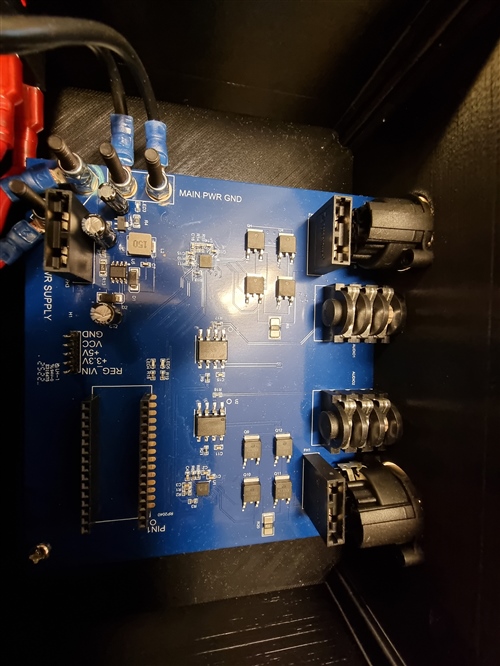

One of my co-workers designed the circuit and a PCB developer in China designed the PCB/component layout for us and produced our first prototype.

The first prototype worked almost 100%...motors were going fine...syncronisation worked flawless but we had some issues with the 5v rail supplying the Arduino.

So we redesigned the circuit. Our designer implented a schottky diode (D2) and increased the capacitance of a capacitor within the DC/DC drop down circuit.

He implented as well an opto isolation IC (6N137s) with integrated 5v/3.3v logic conversion to isolate the feedback signal from the actuators.

Now my big question.

/cfs-file/__key/communityserver-discussions-components-files/38/ORIGINAL-Schematic_5F00_rp2040-tiltvegg_5F00_2021_2D00_10_2D00_28.pdf

The first design has power supply problems regarding Arduino RP2040 but we do not have any issues with the DRV8701P drivers.

The actuators are driving forward and backward as we planned....it is audible that the motor speed is corrected (brake) and the acutators are going in sync.

But the 2nd version is buring the DRV8701P basically instantly and we do not understand why. We did not made any modifications to the DRV8701P circuit and we didn't changed the software....we implemented those 2 opto isolation IC's (U2 and U10), added the schottky diode, increased cap and replaced the contacts for the feedback signal from a 3.5mm to a 6.35mm jack socket.

/cfs-file/__key/communityserver-discussions-components-files/38/wall-contoller-Rev.2.pdf

Could i ask ? Is there an obvious design flaw ?

Those IC are becoming unobtanium and the prices are sky high. We managed to damage 8 chips during troubleshooting and all of those chip are permanently damanged as they are getting hot as the sun as soon as they are powered up. I would appreciate if the TI team could take a look at my design and support me on my way.

Best regards

Christian