Other Parts Discussed in Thread: DRV8811

Hi Expert,

I have two questions about DRV8703-Q1.

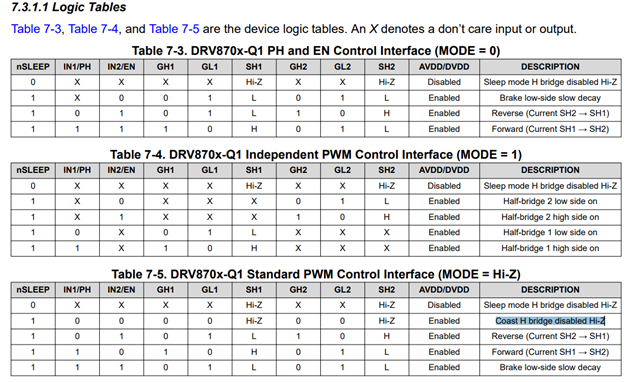

1. Why do we need "Coast H bridge disabled Hi-Z"? What kind of function does it achieve?

2.For below three modes, PWM signal is fed to which pin, EN or PH, in order to achieve speed changing? Thanks.

BR,

Elec Cheng