Hi Team,

Can you please help us regarding the issue with DRV8876PWPR below? According to our customer,

Several DRV8876PWPRs burned out during a lab test with a debugger attached and also in a real product during a test run.

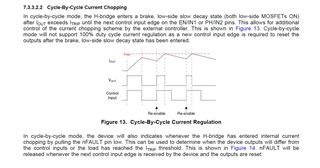

There are numerous cases of failure of the discussed component in the course of software debugging. During debugging, both DRV8876PWPRs used are loaded on brushed motors. These motors are unloaded and draw 150-200 milliamps. Breakpoints are heavily used during debugging. DRV8876PWPR is connected to the microcontroller with 4 lines, as can be seen in the attached diagram. To check, we cut off the nFault line from the microcontroller, but this did not affect the result - the components burned out anyway.

There are also several cases of failures when used in the final product. We design and manufacture robotic pool cleaners. In these cases, the robot functioned under periodic heavy loads on the motors. During the investigation, no traces of thermal effects were found either on the DRV8876PWPR or on the motors.

Please see attached schematic diagram and PCB layout. Can you please help identify the possible cause of this failure?

Regards,

Danilo