Hello,

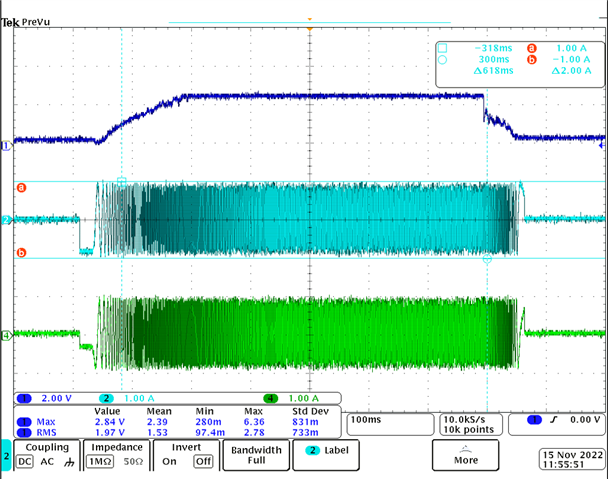

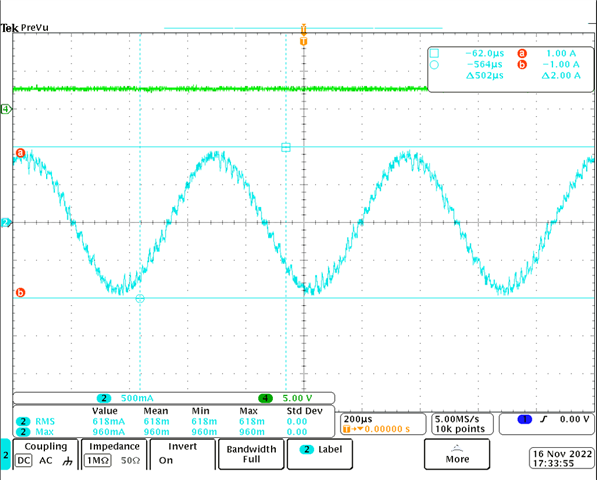

We are using DRV8434A stepper motor driver for our application. For stall monitoring, we are using the driver in Torque count mode. Our external MCU is monitoring the analog voltage at TRQ_CNT/STL_TH pin for stall detection. We are running the motor at 50kHz (STEP input). Microstepping mode is 1/8th step. We have set the ENABLE pin to Hi-Z to enable 8x torque count scaling. The voltage at VREF pin is set to 1.2V.

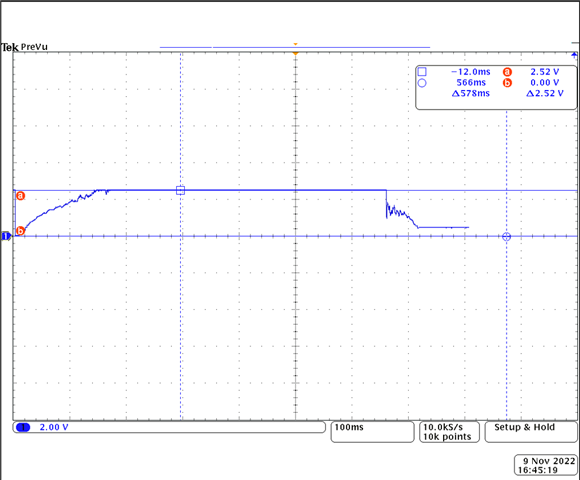

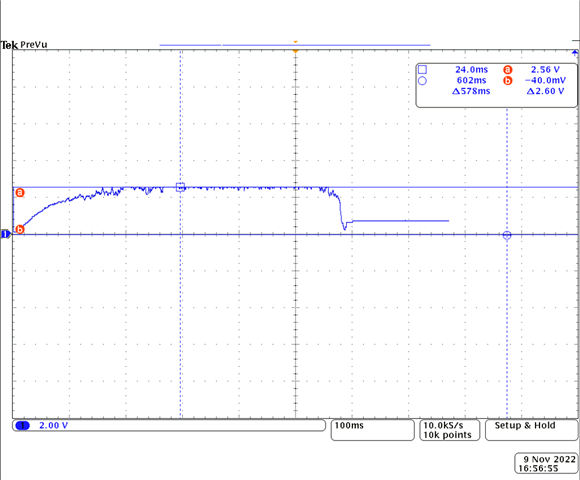

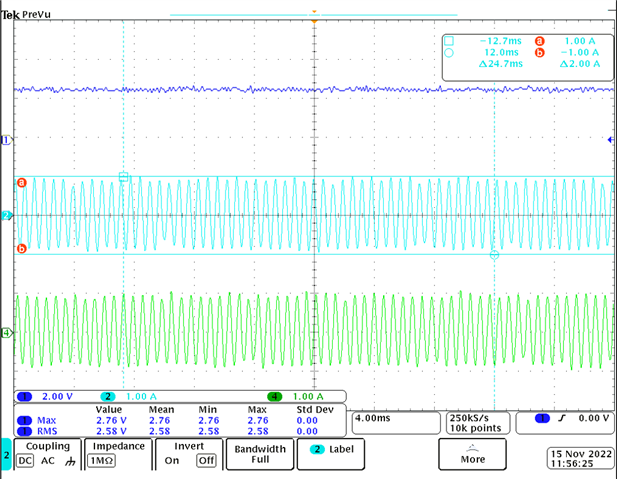

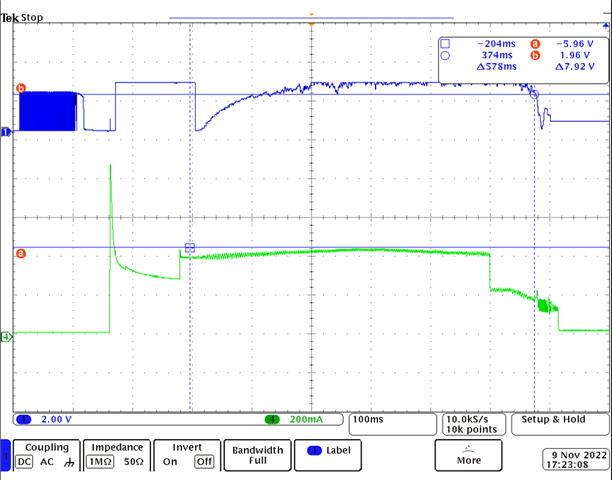

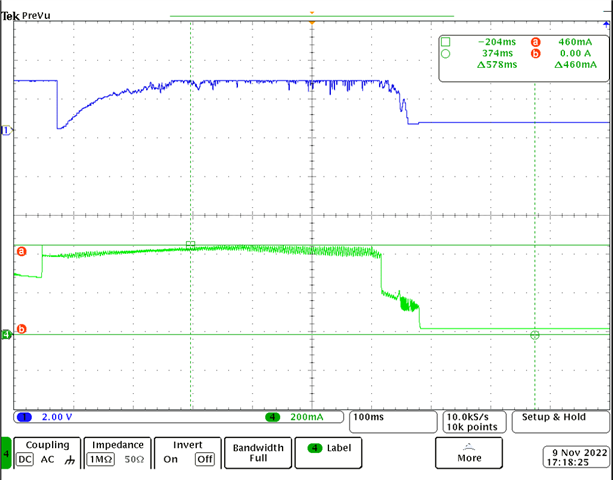

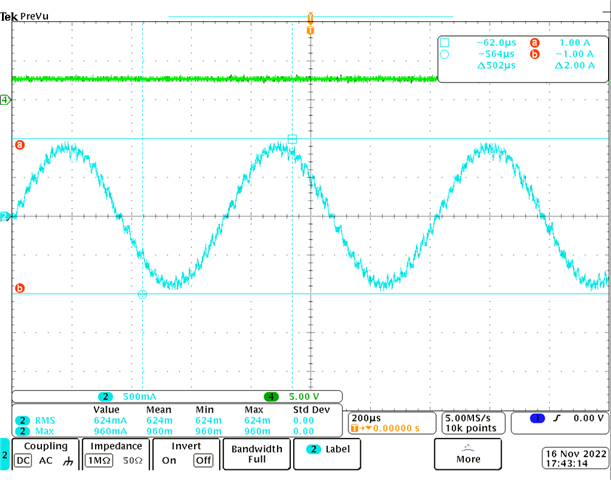

When the motor runs normally without any stall, we see the TRQ-CNT pin give around 2.5V. When the motor stalls, we see a dip in TRQ-CNT. We have set 1.8V as the threshold in our mcu to determine if motor is stalled or not. With this algorithm we are able to detect stall in one type of motor(make 1).

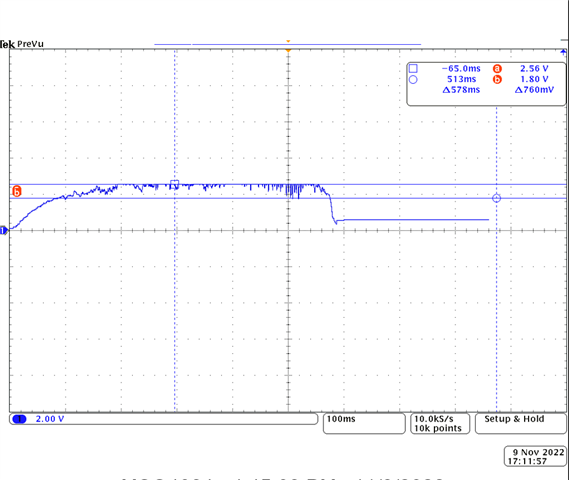

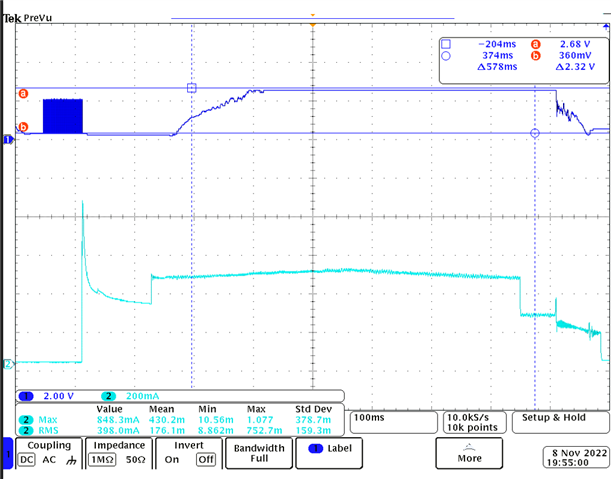

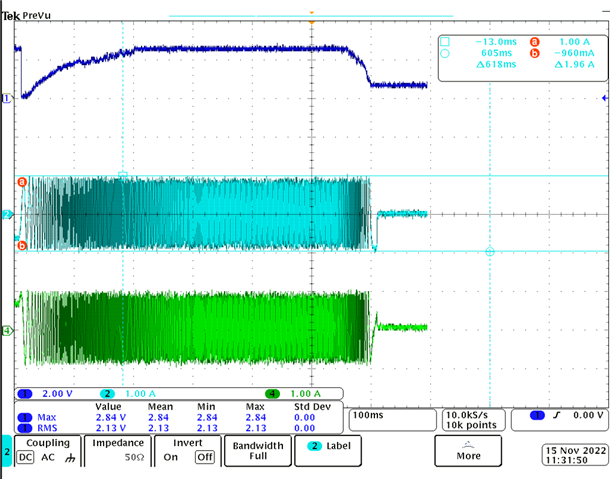

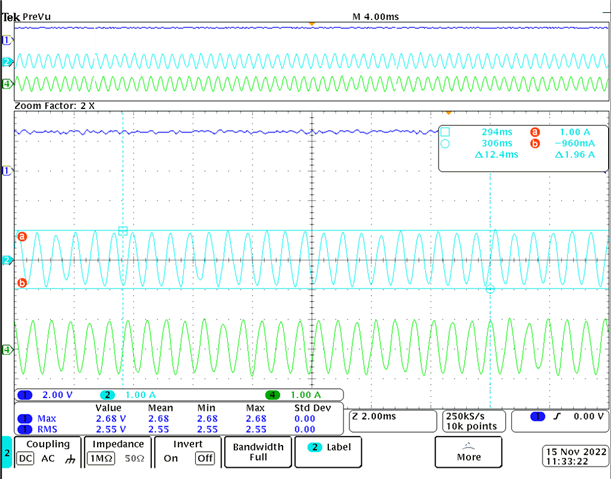

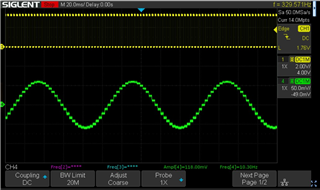

In another motor(make 2 , from a different manufacturer) using the same algorithm, some times we are seeing the TRQ-CNT dip even when the motor is not stalled. The TRQ-CNT is dipping below 1.5V, even when the motor is running freely. This is giving us false positive stall alert.

Stall detection is happening perfectly in make 1 kind of motors. But in make 2 motors we are seeing this issue.

Could you please help us in understanding what might be causing this and help us find a solution for this?

Thank you!