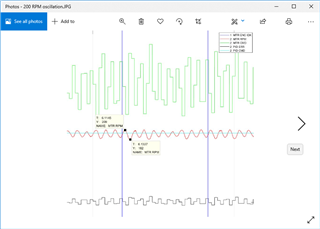

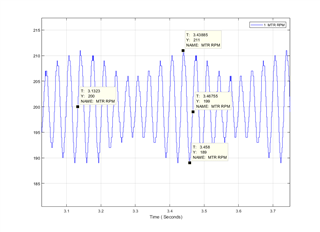

We are using the MCT8316Z controller to drive a small motor from 200RPM up to 6000RPM. The requirement for the control loop is to adjust the PWM into the MCT8316Z to run at a fixed rotational speed that is determined by various system parameters. At low speeds (say 200RPM) we have observed higher than expected variations in the rotational speed even when we run in open loop mode with a fixed PWM setting. There is about +/-5% variation that has a frequency that is a multiple of the rotational speed. The plot below shows the control loop attempting to smooth out the ripple, but really is not able to have any effect at that frequency. I would like help to if there are any of the strap settings for the controller that would be recommended to improve the performance.