Hi team,

Here's an issue from the customer may need your help:

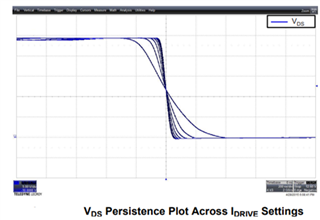

The customer uses an open source project's F28069M Evaluation Board+8305 scheme to control the motor, the firmware is also provided in the original project, and the motor runs smoothly and without noise.This project was followed by the design of an integrated PCB board, known as Micro driver, using the F28069M chip + 8305, which is currently the V2 version.

The same firmware and algorithm are used by the customer to entrust the PCB patch manufacturer with the circuit diagram, and the motor makes a sharp noise and is stuck. As shown in the following video:

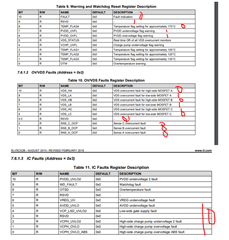

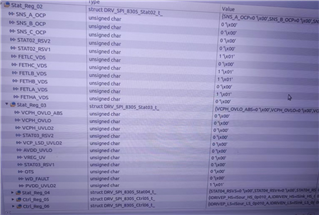

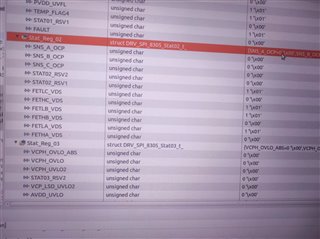

Read back the status of the 8305 through SPI. It is assumed that the nFault issue is reported on the 8305. Here is the value of register 2 of the motor read back:

The circuit diagram for the PCB board is as follows:

Could you help check this case? Thanks.

Best Regards,

Cherry