Hi team,

Here's an issue from the customer may need your help:

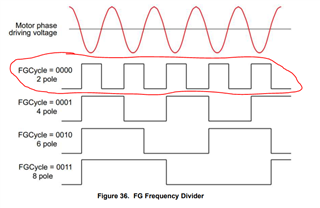

Customer currently uses the register to read speed and it could be consistent with tachometer already. But the speed calculated by capturing the pulse of FG pin is still not correct. How can they get the correct speed through this pin?

The number of polar is 8 and the SysOpt9 in the register is set to "2 electric cycle to send 1 pulse", is "1 electric cycle" here referring to rotate for one time?

Could you help check this case? Thanks.

Best Regards,

Cherry